Allen Bradley Sensors: A Comprehensive Guide to Enhance Your Industrial Automation

Abstract:

This article provides a comprehensive guide on Allen Bradley sensors, focusing on their importance in enhancing industrial automation. It covers various types of sensors, their applications, and the benefits they bring to businesses. Whether you are new to Allen Bradley sensors or looking to optimize their usage, this article will provide valuable insights to help you make informed decisions.

Table of Contents:

1. Introduction

2. Understanding Allen Bradley Sensors

3. Types of Allen Bradley Sensors

4. Applications of Allen Bradley Sensors

5. Benefits of Using Allen Bradley Sensors

6. Tips for Optimizing Allen Bradley Sensors

7. Conclusion

1. Introduction

In the realm of industrial automation, Allen Bradley has emerged as a leading brand known for its reliable and efficient products. Among their wide range of offerings, Allen Bradley sensors play a crucial role in improving operational efficiency and ensuring smooth processes. This article aims to shed light on the importance of Allen Bradley sensors, their diverse applications, and the benefits they bring to businesses.

2. Understanding Allen Bradley Sensors

Allen Bradley sensors are designed to detect, measure, and monitor various parameters in industrial environments. They are instrumental in capturing critical data and providing real-time insights for better decision-making. These sensors are built to withstand harsh conditions, making them ideal for use in demanding industrial settings.

3. Types of Allen Bradley Sensors

Allen Bradley offers a wide range of sensors catering to different industrial needs. Some commonly used types include:

– Proximity sensors: These sensors detect the presence or absence of an object without physical contact.

– Photoelectric sensors: Utilizing light beams, these sensors detect the presence or absence of objects or measure distances.

– Pressure sensors: Measuring pressure changes, these sensors ensure optimal performance and safety in systems.

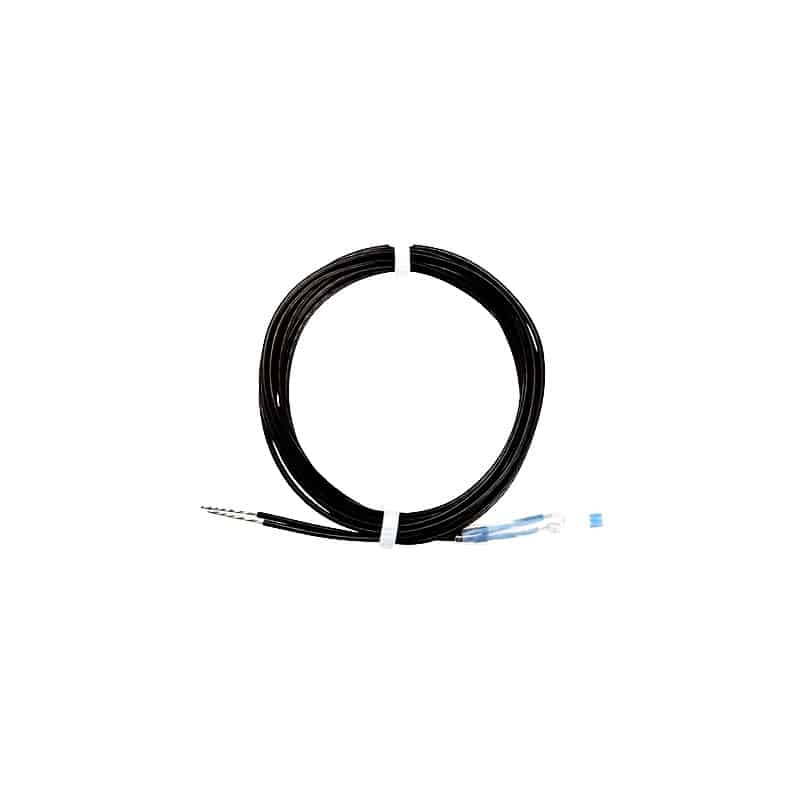

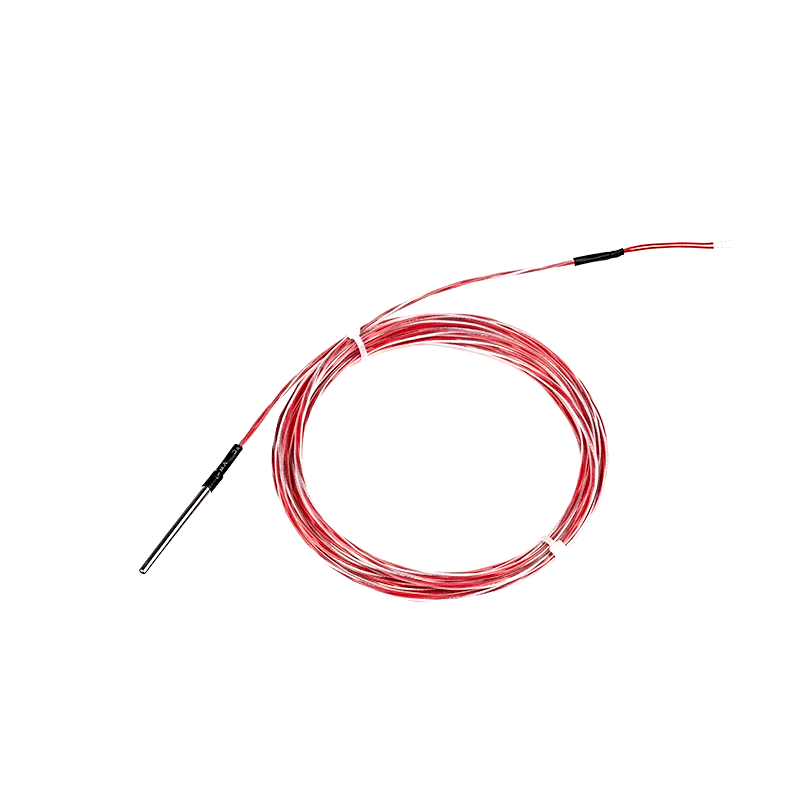

– Temperature sensors: These sensors monitor temperature variations, enabling precise control and preventing equipment damage.

4. Applications of Allen Bradley Sensors

Allen Bradley sensors find extensive applications across various industries. Some notable examples include:

– Manufacturing: Sensors play a crucial role in automating manufacturing processes, optimizing efficiency, and ensuring consistent quality.

– Automotive: From assembly lines to quality control, sensors are essential for smooth operations and maintaining high standards.

– Food and Beverage: Sensors help monitor critical parameters such as temperature, pressure, and level, ensuring food safety and regulatory compliance.

– Pharmaceuticals: Precise monitoring and control of variables are vital in pharmaceutical production, where Allen Bradley sensors excel.

5. Benefits of Using Allen Bradley Sensors

Incorporating Allen Bradley sensors into your industrial automation system offers numerous benefits:

– Enhanced Productivity: With accurate data collection and real-time insights, businesses can optimize production processes, leading to increased productivity.

– Improved Quality: Allen Bradley sensors ensure consistent monitoring, ensuring products meet stringent quality standards.

– Cost Savings: Proactive monitoring and timely maintenance, facilitated by sensors, minimize downtime and prevent costly equipment failures.

– Workplace Safety: Sensors enable the detection of hazardous conditions, promoting a safer work environment for employees.

– Regulatory Compliance: By monitoring critical parameters, businesses can adhere to industry regulations and avoid penalties.

6. Tips for Optimizing Allen Bradley Sensors

To maximize the benefits of Allen Bradley sensors, consider the following tips:

– Regular Maintenance: Schedule routine maintenance to ensure sensors are calibrated, clean, and functioning optimally.

– Proper Placement: Position sensors strategically to capture accurate data and minimize false readings.

– Training and Education: Train personnel on sensor usage, troubleshooting techniques, and best practices to ensure effective utilization.

– Integration with Control Systems: Integrate sensors seamlessly with control systems for streamlined data collection and analysis.

7. Conclusion

Allen Bradley sensors are an integral part of industrial automation, enabling businesses to achieve higher efficiency, quality, and safety standards. Understanding the different types of sensors, their applications, and the benefits they offer is essential for making informed decisions. By optimizing the usage of Allen Bradley sensors and following best practices, businesses can unlock their full potential and stay ahead in today’s competitive market.

Remember, Allen Bradley sensors are not just components; they are enablers of progress and success in industrial automation. Embrace their capabilities, harness their power, and propel your business to new heights.

(Note: This article is intended for informational purposes only and does not endorse any specific brand or product. Always consult with experts before making any investment or technical decisions in your respective industries.)

The Impact of Temperature Sensors on Modern Energy Solutions

In the rapidly evolving world of energy solutions, temperature sensors play a crucial role in ensuring efficiency and safety. These sophisticated devices are integral to the functionality of various systems,