The industrial landscape is constantly evolving, driven by the need for precision, efficiency, and reliability. At the forefront of this transformation are thermistor sensors, particularly the MF52D NTC thermistor, which has become a cornerstone in temperature detection across various sectors. As thermistor manufacturers continue to innovate, these devices are revolutionizing processes in manufacturing, quality control, and safety monitoring. Starlightsensors, established in 2009, has emerged as a leading force among thermistor suppliers, offering high-quality temperature sensing solutions that cater to the diverse needs of modern industries.

Table of contents:

Optimizing Manufacturing Processes Using MF52D NTC Thermistors

The Role of Thermistor Temperature Sensors in Quality Control

Enhancing Industrial Safety with Reliable Thermistor Technology

Cost-Effective Temperature Monitoring Solutions Using Thermistor Sensors

Optimizing Manufacturing Processes Using MF52D NTC Thermistors

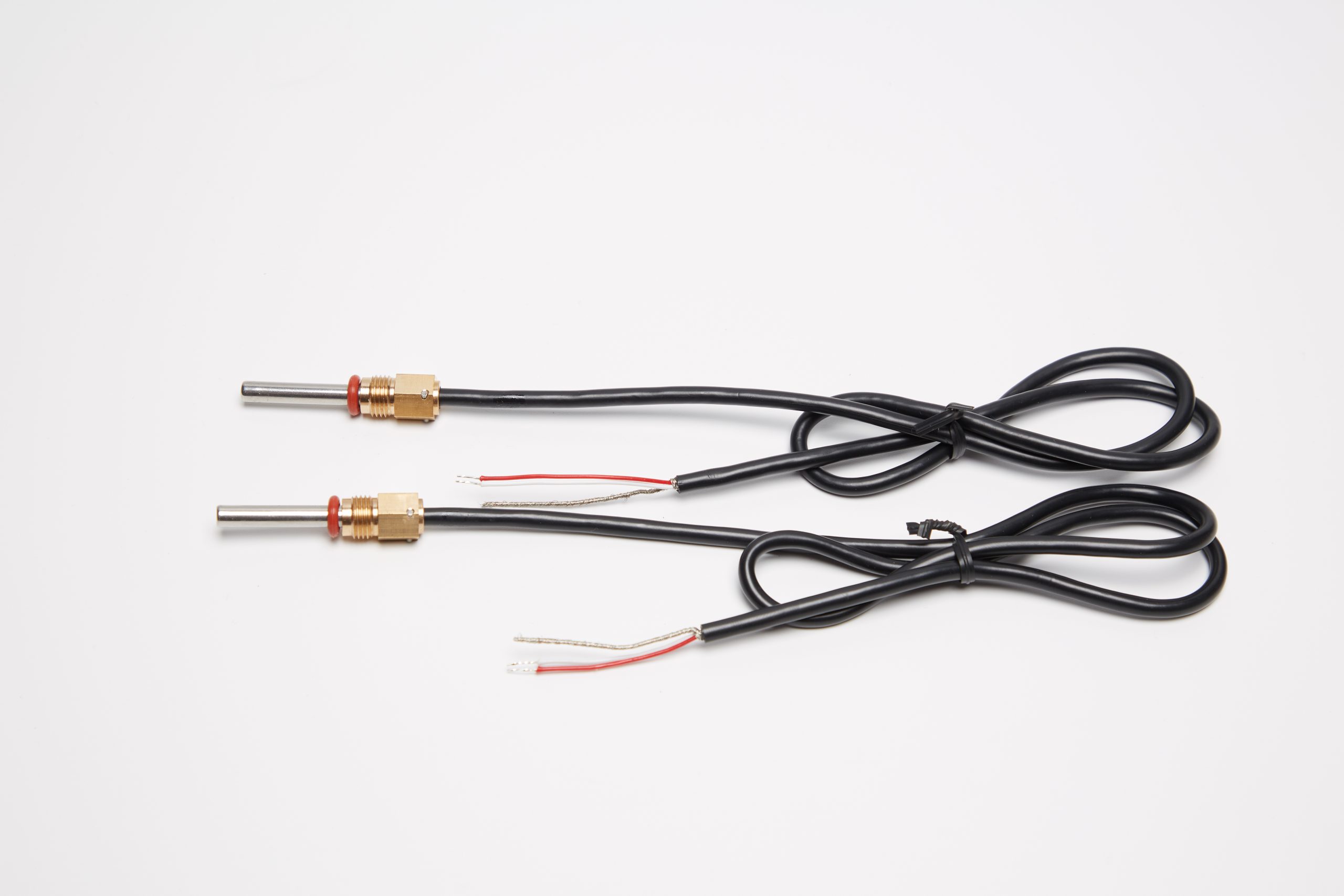

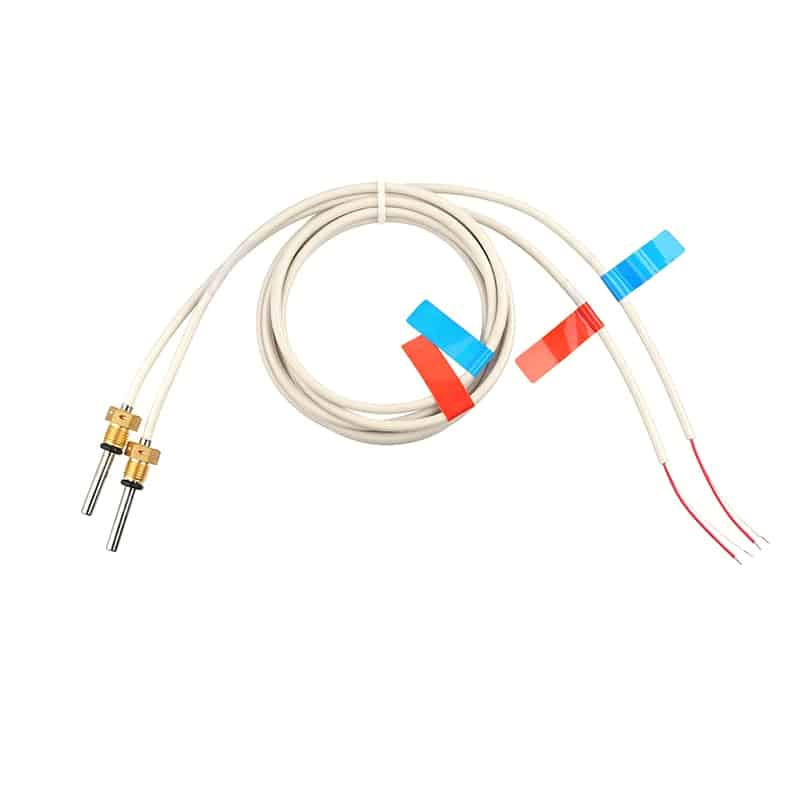

The MF52D NTC thermistor has become an indispensable tool in optimizing manufacturing processes. With its high accuracy in resistance value and B value, coupled with excellent consistency, this sensor enables precise temperature control in production lines. Thermistor manufacturers have designed these components to offer a fast response speed and high sensitivity, allowing for real-time adjustments in industrial settings. The wide resistance range of 0.1-500KΩ makes the MF52D versatile enough to be integrated into various applications, from home appliances to complex industrial equipment. As thermistor suppliers continue to refine their products, manufacturers benefit from enhanced process stability and reduced waste.

The Role of Thermistor Temperature Sensors in Quality Control

Quality control is paramount in modern manufacturing, and thermistor temperature sensors play a crucial role in maintaining high standards. The MF52D NTC thermistor’s ability to provide consistent and accurate temperature readings is invaluable in ensuring product quality across different industries. Thermistor manufacturers have developed these sensors to withstand extreme temperatures, with an operating range of -30°C to 125°C, making them suitable for diverse quality control applications. From monitoring the temperature of electronic devices to ensuring the proper functioning of medical instruments, thermistor suppliers like Starlightsensors offer solutions that help businesses maintain strict quality control measures and meet regulatory requirements.

Enhancing Industrial Safety with Reliable Thermistor Technology

Safety is a top priority in any industrial setting, and thermistor technology plays a vital role in maintaining a secure work environment. The MF52D NTC thermistor’s rapid response to temperature changes makes it an excellent choice for safety-critical applications such as fire alarms and overheating protection systems. Thermistor manufacturers have focused on creating robust sensors that can reliably detect temperature anomalies, preventing potential accidents and equipment failures. As thermistor suppliers continue to innovate, industries benefit from more sophisticated safety systems that can quickly identify and respond to thermal risks, safeguarding both personnel and assets.

Cost-Effective Temperature Monitoring Solutions Using Thermistor Sensors

In today’s competitive business landscape, cost-effectiveness is crucial, and thermistor sensors offer an economical solution for temperature monitoring needs. Thermistor manufacturers like Starlightsensors provide high-quality products at competitive prices, allowing businesses to implement comprehensive temperature monitoring systems without breaking the bank. The versatility of the MF52D NTC thermistor means that a single sensor type can be used across multiple applications, from consumer electronics to automotive temperature measurement, reducing inventory costs for companies. Additionally, the durability and longevity of these sensors contribute to lower maintenance and replacement expenses over time, making them a smart investment for industries seeking reliable, long-term temperature monitoring solutions.

The impact of advanced thermistor sensors on industrial efficiency cannot be overstated. As thermistor manufacturers continue to push the boundaries of accuracy and reliability, industries across the board are reaping the benefits of improved process control, enhanced quality assurance, and heightened safety measures. The MF52D NTC thermistor exemplifies the potential of these sensors, offering a combination of precision, versatility, and cost-effectiveness that is transforming industrial operations. With trusted thermistor suppliers like Starlightsensors at the helm, businesses can confidently embrace these technologies, knowing they have access to cutting-edge temperature sensing solutions backed by expertise and support. As industries continue to evolve, the role of thermistor sensors in driving efficiency, quality, and safety will only grow more significant, cementing their place as essential components in the industrial landscape of the future.