In the ever-evolving landscape of industrial applications, precise temperature measurement is crucial for maintaining quality and efficiency. Thermocouple probes have emerged as indispensable tools in this regard, offering high accuracy and reliability. A notable aspect of these sensors is their ability to perform exceptionally well in harsh environments. Thermocouple manufacturers, like Starlightsensors, have been at the forefront of developing advanced solutions that cater to industries requiring stringent temperature control. The integration of sophisticated mechanisms and robust construction ensures these sensors deliver consistent performance, making them a preferred choice among thermocouple suppliers globally.

Table of contents:

The Importance of Spring-Loaded Mechanisms in Thermocouple Sensors

Achieving Reliable Temperature Readings with Advanced Thermocouple Technology

Adapting Thermocouple Temperature Sensors to Various Industrial Applications

Future-Proofing Your Processes with Versatile Thermocouple Probes

The Importance of Spring-Loaded Mechanisms in Thermocouple Sensors

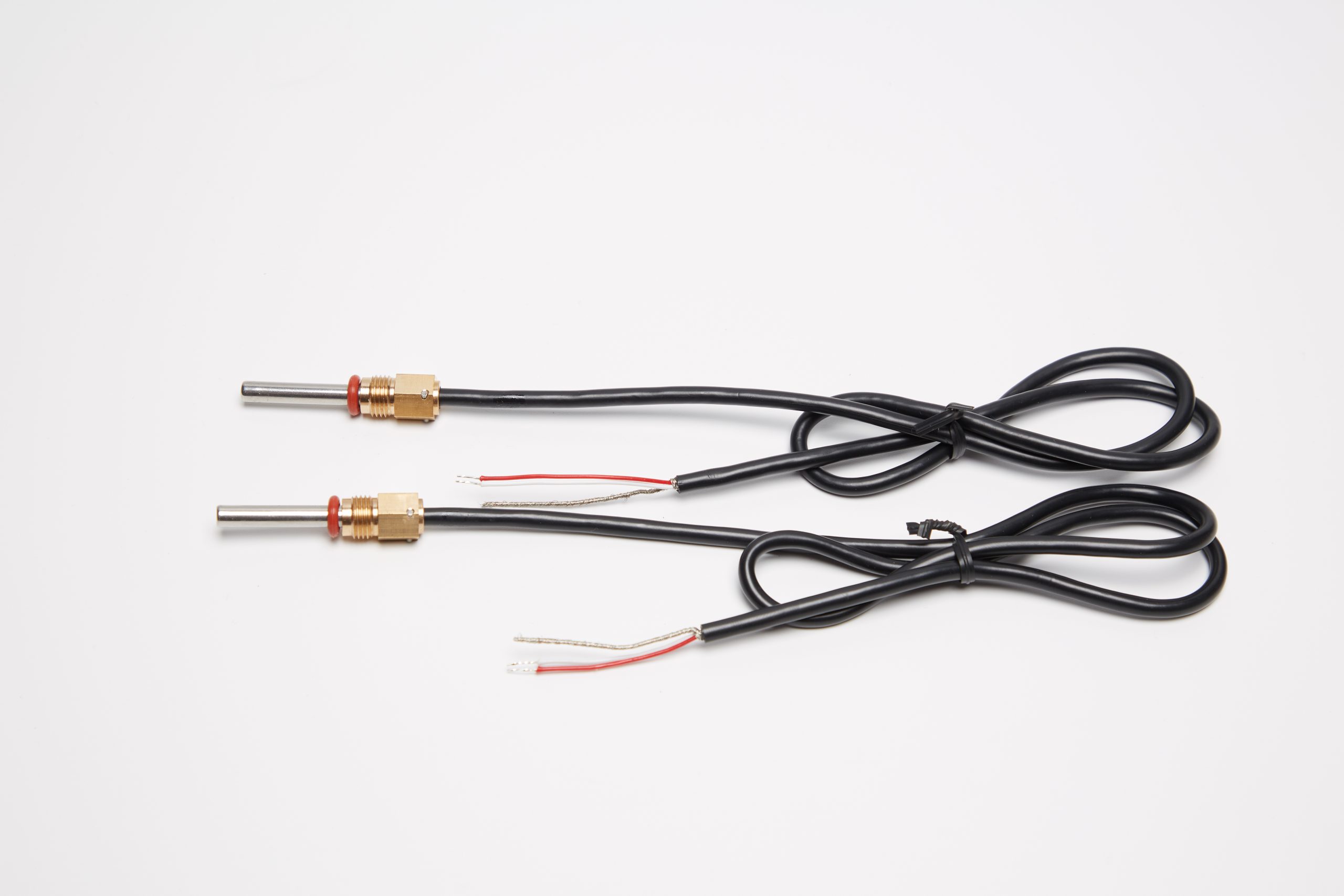

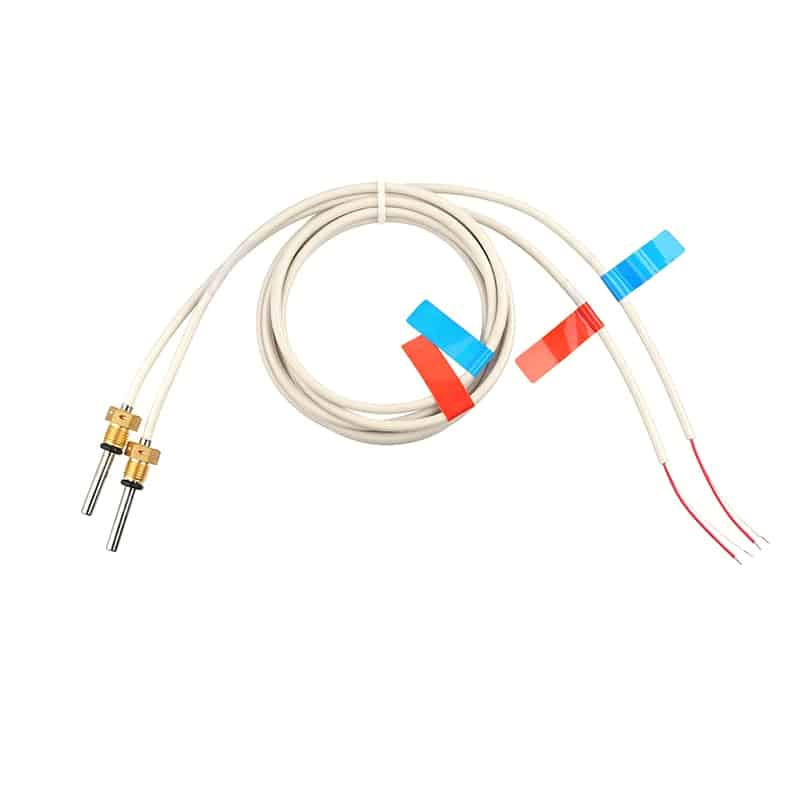

Spring-loaded mechanisms play a pivotal role in the functionality of thermocouple sensors. These mechanisms ensure that the sensor maintains firm contact with the surface being measured, which is critical for obtaining accurate temperature readings. In demanding environments, where conditions can fluctuate drastically, this feature becomes even more essential. The spring-loaded design compensates for any movement or vibration, thereby preventing any disruption in the measurement process. Thermocouple suppliers often emphasize the significance of this feature when advising industries on sensor selection. By guaranteeing consistent contact, these sensors help maintain the integrity of temperature data, which is vital for process optimization and quality control.

Achieving Reliable Temperature Readings with Advanced Thermocouple Technology

Advanced thermocouple technology has revolutionized the way industries approach temperature measurement. Incorporating K-Type and E-Type technology, these sensors provide enhanced performance and accuracy. This innovation is particularly beneficial for applications such as injection molding machines, where precision is paramount. Thermocouple manufacturers have dedicated significant resources to research and development to ensure their products meet the highest standards of accuracy and reliability. As a result, industries can rely on these sensors for consistent and precise temperature readings, which are crucial for maintaining product quality and operational efficiency. The advanced technology embedded in these sensors sets them apart from conventional temperature measurement solutions, making them a valuable asset for any industrial setup.

Adapting Thermocouple Temperature Sensors to Various Industrial Applications

The versatility of thermocouple temperature sensors is one of their most compelling features. These sensors can be adapted to a wide range of industrial applications, from manufacturing to energy production. Thermocouple suppliers offer customized solutions to meet the specific needs of different industries, ensuring that each application receives the most suitable sensor configuration. Whether it’s dealing with extreme temperatures or corrosive environments, these sensors are designed to withstand the challenges posed by various industrial settings. This adaptability not only enhances their functionality but also extends their lifespan, providing industries with a cost-effective and reliable temperature measurement solution.

Future-Proofing Your Processes with Versatile Thermocouple Probes

As industries continue to evolve, the need for future-proof temperature measurement solutions becomes increasingly important. Versatile thermocouple probes are designed to meet this demand by offering flexibility and durability. Thermocouple manufacturers are constantly innovating to improve the design and functionality of these sensors, ensuring they can adapt to emerging industrial trends. By investing in high-quality thermocouple probes, industries can safeguard their processes against future challenges. Thermocouple suppliers play a crucial role in this by providing expert guidance and support, helping industries select the most appropriate sensors for their specific needs. This proactive approach ensures that temperature measurement systems remain effective and efficient, regardless of future developments.

In summary, thermocouple probes have become essential components in the realm of temperature control, particularly in harsh environments. Their advanced technology, combined with features like spring-loaded mechanisms, ensures accurate and reliable readings, which are vital for maintaining industrial efficiency. Thermocouple manufacturers and suppliers continue to innovate, offering versatile and adaptable solutions that cater to a wide range of applications. By choosing the right thermocouple sensors, industries can not only optimize their current processes but also prepare for future challenges, ensuring sustained success and competitiveness in the market.