In the highly competitive field of injection molding, precision and efficiency are paramount. Thermocouple sensors play a crucial role in maintaining these standards by providing accurate temperature measurements. For industries that rely on precise temperature control, such as plastics manufacturing, the right choice of thermocouple sensors can significantly impact productivity and product quality. Thermocouple manufacturers and thermocouple suppliers are pivotal in delivering high-quality sensors that meet the rigorous demands of industrial applications. These sensors, like the high-precision spring-loaded K-Type and E-Type thermocouples from Starlightsensors, ensure reliable performance even in challenging conditions. By understanding the benefits and applications of these advanced sensors, businesses can enhance their operational efficiency and maintain a competitive edge in the market.

Table of contents:

Understanding the Role of Thermocouple Temperature Sensors in Industrial Applications

How Thermocouple Probes Enhance Accuracy in Temperature Measurement

The Advantages of Spring-Loaded Thermocouple Sensors for Consistent Readings

Integrating K-Type & E-Type Thermocouple Sensors for Superior Performance

Understanding the Role of Thermocouple Temperature Sensors in Industrial Applications

Thermocouple temperature sensors are indispensable tools in various industrial applications, especially those requiring precise temperature monitoring. These sensors are designed to measure temperature by converting thermal potential difference into an electrical signal. Thermocouple manufacturers provide a range of sensor types, each tailored to specific industry needs. In injection molding, for instance, maintaining consistent temperatures is essential to ensure the quality of the molded products. The high-precision sensors from thermocouple suppliers like Starlightsensors offer the accuracy required to achieve these consistent results. Their robust construction allows them to withstand harsh environments, making them suitable for a wide array of industrial settings. By integrating these sensors, industries can ensure that their processes remain efficient and their products meet the highest quality standards.

How Thermocouple Probes Enhance Accuracy in Temperature Measurement

Thermocouple probes are vital components in the realm of temperature measurement, known for their ability to provide precise and reliable readings. These probes are engineered to detect temperature changes swiftly, ensuring that any deviations from the set parameters are promptly addressed. Thermocouple manufacturers design these probes to meet the stringent demands of industries that rely on accurate temperature data. In injection molding, where even minor temperature fluctuations can lead to defects, the precision of thermocouple probes is invaluable. Thermocouple suppliers offer a variety of probes, including the advanced K-Type and E-Type, which are known for their sensitivity and reliability. By employing these probes, industries can enhance their temperature control processes, leading to improved product consistency and reduced waste.

The Advantages of Spring-Loaded Thermocouple Sensors for Consistent Readings

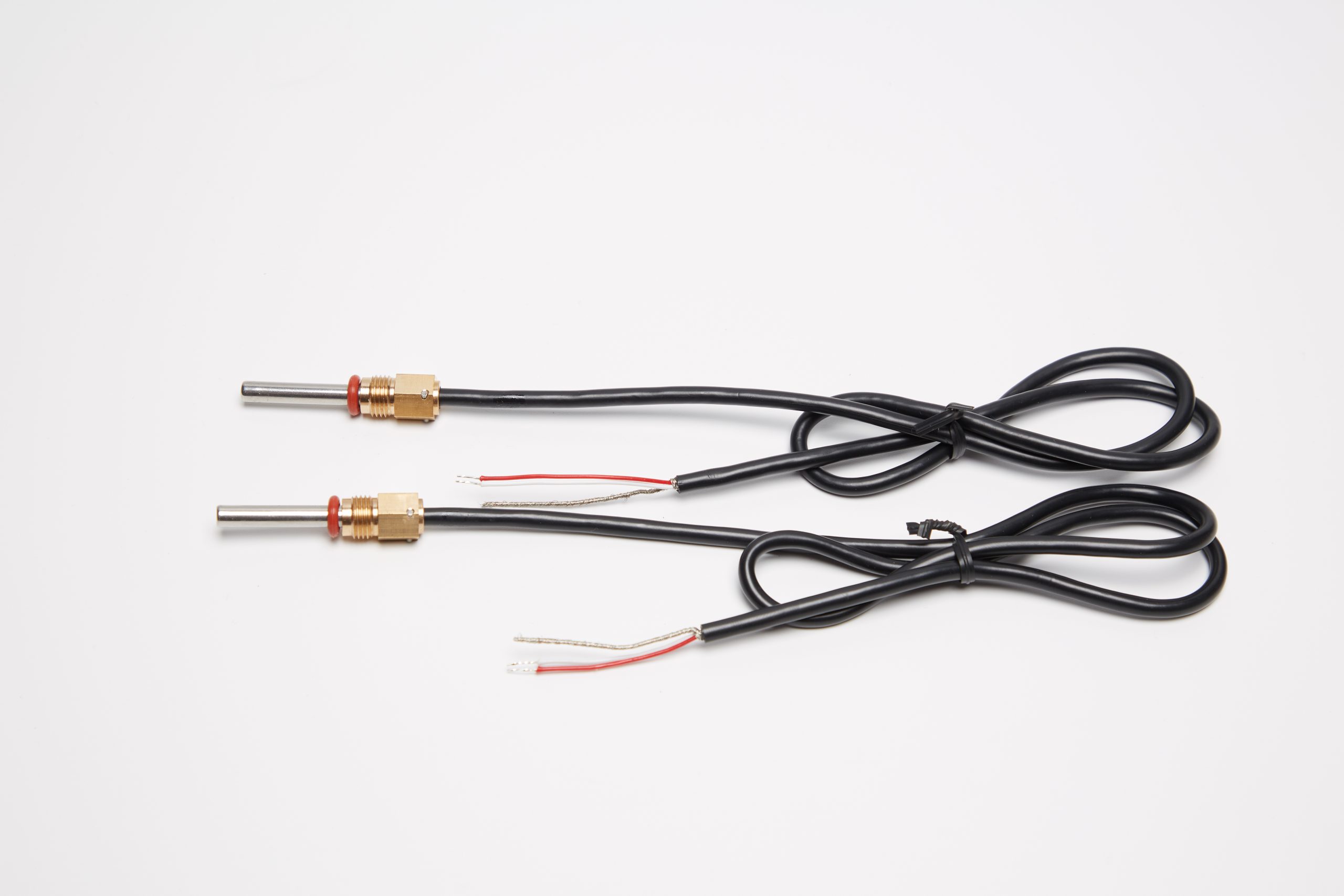

Spring-loaded thermocouple sensors are designed to maintain consistent contact with the measurement surface, ensuring accurate readings even in dynamic environments. This feature is particularly beneficial in applications where the sensor must adapt to changes in the measurement surface, such as in injection molding machines. Thermocouple manufacturers have developed spring-loaded sensors to address the challenges posed by fluctuating conditions. These sensors, available from leading thermocouple suppliers, are engineered to provide stable and reliable measurements, reducing the risk of errors. The spring-loaded mechanism ensures that the sensor remains in optimal contact, even as the machine operates at high speeds. This consistency in temperature measurement is crucial for maintaining the quality and efficiency of industrial processes, making spring-loaded sensors a valuable asset in any temperature-sensitive application.

Integrating K-Type & E-Type Thermocouple Sensors for Superior Performance

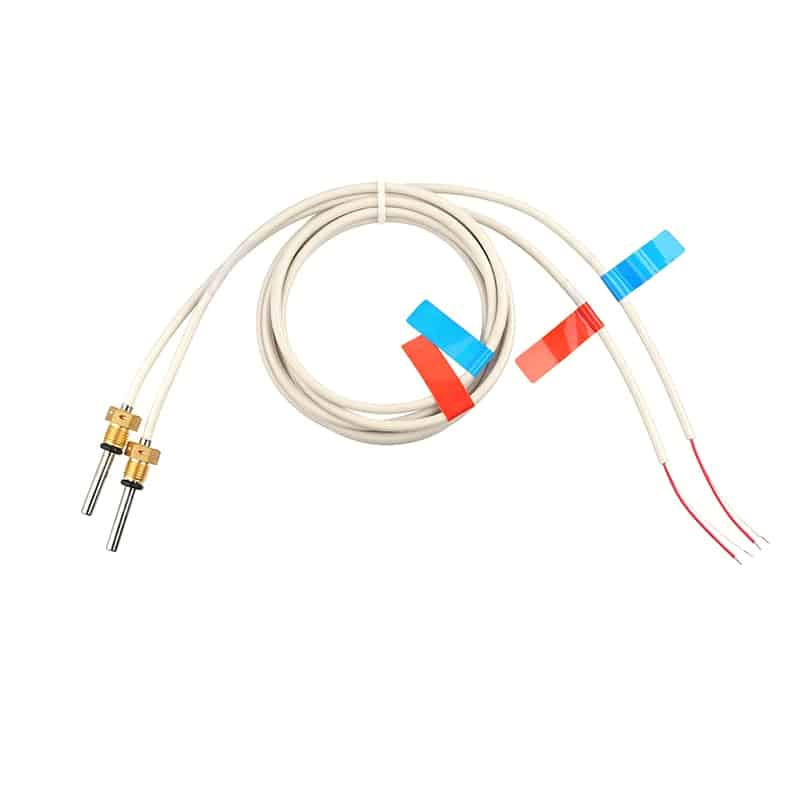

K-Type and E-Type thermocouple sensors are renowned for their versatility and performance in various industrial applications. These sensors are designed to provide accurate temperature readings across a wide range of conditions, making them ideal for industries such as injection molding. Thermocouple manufacturers have developed these sensors to offer enhanced performance, ensuring that they can meet the specific needs of different applications. Thermocouple suppliers like Starlightsensors provide these advanced sensors, which integrate cutting-edge technology to deliver superior accuracy and reliability. By incorporating K-Type and E-Type sensors into their systems, industries can achieve better temperature control, leading to improved process efficiency and product quality. The ability to maintain precise temperature measurements is a key factor in optimizing industrial operations, and these sensors play a crucial role in achieving that goal.

In summary, the integration of high-precision thermocouple sensors in industrial applications, particularly in injection molding, is essential for maintaining efficiency and product quality. Thermocouple manufacturers and thermocouple suppliers provide a variety of sensors, including spring-loaded, K-Type, and E-Type, each designed to meet the specific demands of different industries. These sensors ensure accurate and consistent temperature measurements, which are critical for optimizing industrial processes. By leveraging the advanced technology offered by these sensors, businesses can enhance their operational performance and remain competitive in the market. The expertise of thermocouple manufacturers and the quality of products from thermocouple suppliers are instrumental in delivering the precision and reliability needed for success in temperature-sensitive applications.