Introduction NTC (Negative Temperature Coefficient) thermistors are essential components used in various electronic devices for precise temperature measurement and control. Their resistance decreases as the temperature rises, making them ideal for many applications. However, like any electronic part, they can experience errors or malfunctions that affect performance. In this guide, we’ll explore common NTC thermistor issues, troubleshooting steps, and preventive strategies.

Common NTC Thermistor Errors

Understanding frequent NTC thermistor errors is key to identifying and resolving issues efficiently. Some of the most typical problems include:

- Open Circuit: This occurs when the NTC thermistor is physically disconnected or has a broken connection, leading to a lack of temperature measurement data.

- Short Circuit: In this error, the circuit forms an unintended connection, which causes incorrect temperature readings or may even damage the surrounding circuitry.

- Resistance Drift: Over time, NTC thermistors may change their resistance characteristics due to aging, wear, or environmental exposure, resulting in inaccurate measurements.

- Interference: Electromagnetic interference (EMI) from nearby electronic devices or power sources can disturb the thermistor’s signals, leading to faulty readings.

Troubleshooting NTC Thermistor Errors

When troubleshooting issues with an NTC thermistor, these steps can help identify and resolve the problem:

- Check Connections: Ensure that the NTC thermistor is properly connected to the circuit. Look for loose wires or damaged connections, and tighten or replace them as necessary.

- Inspect for Physical Damage: Examine the thermistor for cracks, burns, or discoloration. If physical damage is detected, replace the thermistor.

- Measure Resistance: Use a multimeter to measure the thermistor’s resistance at various temperatures and compare these values to the expected specifications. Significant deviations may indicate a faulty thermistor.

- Reduce Electromagnetic Interference: Move the thermistor circuit away from sources of EMI, such as motors, power lines, or other high-power devices. Shielding the circuit may also help reduce interference.

Preventive Measures

Preventing errors from occurring in the first place is critical to ensuring long-term reliability of NTC thermistors. The following steps can help:

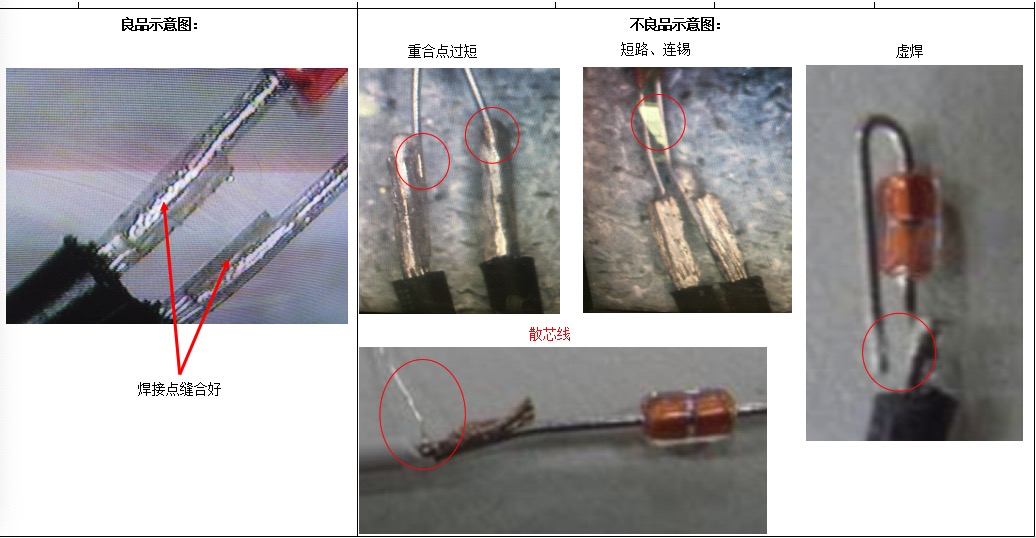

- Proper Soldering Techniques: When attaching the NTC thermistor to a circuit board, use proper soldering methods to ensure stable connections and avoid potential disconnections.

- Choose High-Quality Components: Invest in NTC thermistors from trusted manufacturers that offer reliable performance and longevity. Poor-quality components are more prone to failure and drift.

- Insulation and Protection: Ensure that the thermistor circuit is well-insulated to protect it from environmental factors like moisture, dust, or extreme temperatures, which could affect performance.

- Regular Calibration: Periodically calibrate the thermistors to maintain accuracy, especially in applications where precise temperature readings are crucial. Regular testing helps detect resistance drift or deviations early.

- Conduct 100% post-soldering inspection using CCD detection equipment to thoroughly inspect the appearance of the thermistor, ensuring flawless solder quality and preventing any soldering defects.

Conclusion

NTC thermistors are widely used for temperature sensing in many electronic systems. However, they can encounter errors such as open circuits, short circuits, resistance drift, or EMI interference. By understanding common problems, following troubleshooting procedures, and taking preventive measures like proper installation and regular calibration, you can ensure accurate temperature control and prolong the lifespan of your thermistors.