Introduction: RTD sensors enhance new energy safety by monitoring electric vehicle motors within -60℃ to +230℃, ensuring efficiency and longevity.

Imagine a world where electric vehicles operate seamlessly, their engines running efficiently, without overheating, and their batteries lasting longer than ever. This scenario paints a picture of innovation in the new energy sector, largely supported by the precision and reliability of RTD temperature sensors. These sensors, typically produced by leading rtd sensor manufacturers, play an integral role in securing and optimizing the performance of various components within this ecosystem. Designed to monitor temperatures accurately across different applications, units from an rtd temperature sensors manufacturer ensure safety and efficiency, making them indispensable in modern technological advancements.

Key features of RTD sensors for electric vehicle motor protection

Electric vehicles have transformed transportation, but with this evolution comes the need for high-tech solutions to protect their sensitive components. RTD temperature sensors, carefully engineered by reputable rtd sensor manufacturers, ensure that electric vehicle motors do not overheat by closely monitoring their temperature levels. These sensors are designed to function within a broad temperature range—from -60℃ to +230℃—an attribute that assures consistent performance under varying driving conditions. With accuracy classes ranging from 1/3 Class B to Class B, these sensors provide the clarity needed to maintain operational stability. By incorporating silver-plated Teflon wires, they promise not only excellent insulation but also high voltage resistance, essential for withstanding the high-energy demands of electric motors. Additionally, the longevity of these sensors is noteworthy, maintaining less than a 0.04% change after 1000 hours of usage, which underscores their reliability. As a product of esteemed rtd sensor manufacturers, these RTD sensors ensure electric vehicles run without disruptions, aligning with new energy goals for safer and more reliable transport solutions.

Advantages of platinum resistance RTD sensors in battery aging monitoring

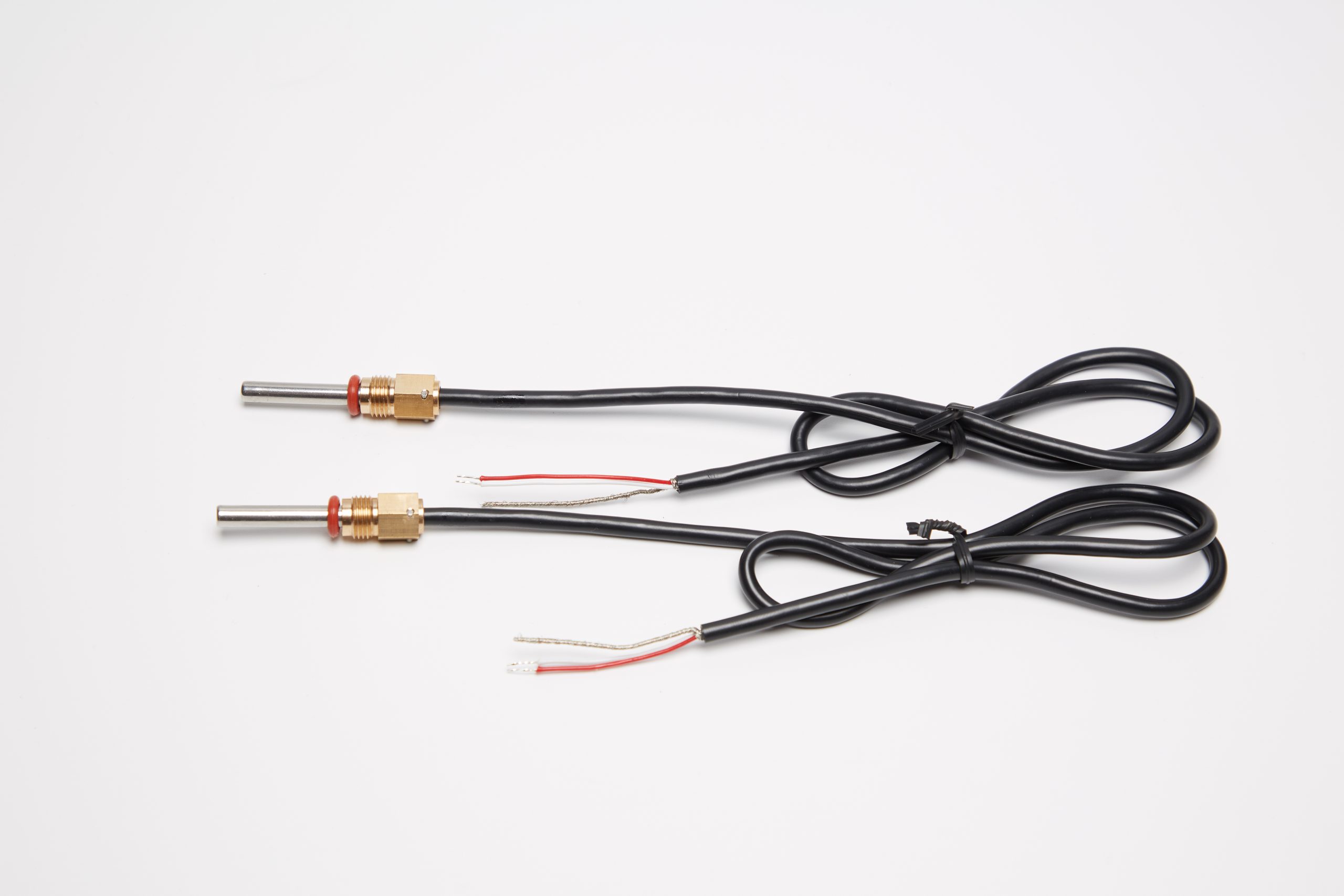

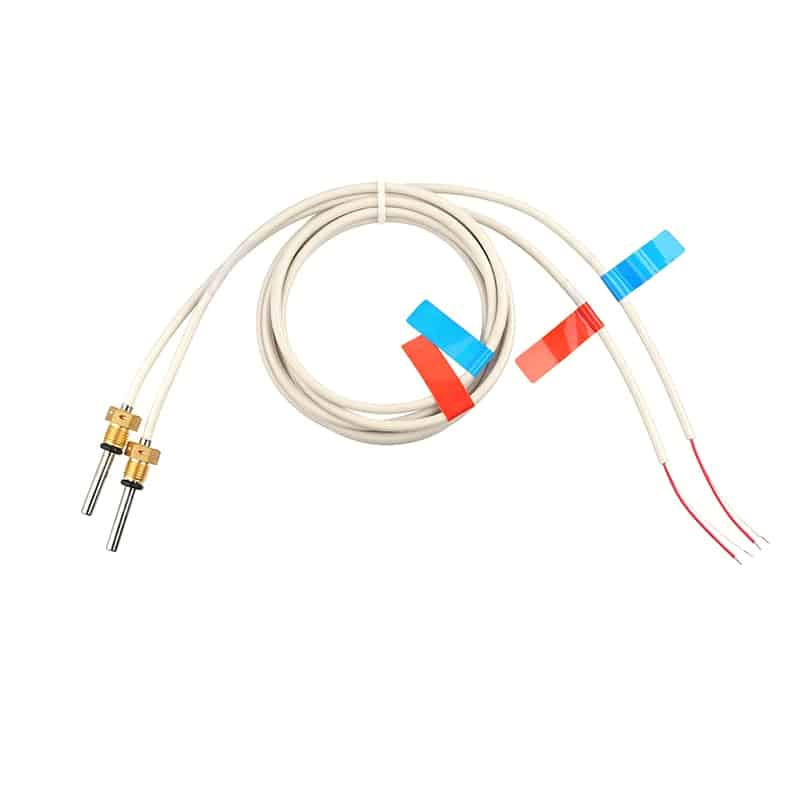

The longevity and reliability of electric vehicle batteries are greatly enhanced through rigorous battery aging monitoring, facilitated by platinum resistance RTD sensors. Renowned rtd sensor manufacturers craft these sensors to offer near-linear temperature dependence, providing exquisite precision and interchangeability. This feature is remarkably beneficial when assessing battery performance over time. By being housed in durable materials like 304 stainless steel and PTFE Teflon rubber, these sensors can withstand high temperatures while transmitting accurate resistance data. Their compact design ensures they fit effortlessly within the tight confines of battery compartments. Furthermore, their rapid response to temperature fluctuations allows for timely data collection, essential for understanding the wear and degradation of battery cells. This scientific feedback loop helps in preemptively addressing potential failures, thereby extending battery life and maintaining energy efficiency. With customization options available such as NTC thermistor signal outputs and varying wire lengths, these sensors are adept for diverse battery configurations. The commitment of an rtd temperature sensors manufacturer to innovate means these sensors serve as a linchpin for understanding and improving battery performance, driving forward the ambitions of sustainable and reliable energy use.

Integration of two-wire and three-wire communication in temperature sensors

In the realm of advanced temperature measurement, the integration of two-wire and three-wire communication systems in RTD sensors is a testament to ultra-modern engineering. These configurations, designed by forward-thinking rtd sensor manufacturers, offer distinct advantages in enhancing signal accuracy and reducing potential measurement errors. The two-wire system is often employed in scenarios demanding a simplification of design, where reduced wiring benefits outweigh the susceptibility to lead wire resistance impacts. However, the three-wire iteration strikes a balance by significantly reducing lead resistance errors, making it favorable for applications requiring heightened precision. The inclusion of insulation resistance greater than or equal to 100MΩ at 500VDC ensures these sensors can perform even under demanding electrical conditions. Such intricacies allow an rtd temperature sensors manufacturer to cater to diverse industrial needs, ensuring that temperature-related data remains untainted by extraneous electrical noise. This flexibility is particularly beneficial for new energy applications, where precision and reliability are non-negotiable. By integrating these communication modes, rtd sensor manufacturers offer solutions that not only meet current technical demands but also anticipate future innovations in temperature sensing technology.

The significance of RTD temperature sensors in the new energy sector cannot be overstated. Built to ensure accuracy and reliability, these sensors, crafted by dedicated rtd sensor manufacturers, are at the forefront of technological safety and efficiency. Whether monitoring electric vehicle motor temperatures or assessing battery longevity, these sensors provide invaluable insights, underscoring a commitment to innovation and progress. As the integration of varying communication systems enhances their versatility, these sensors seamlessly align with the evolving demands of the industry. Designed with durability in mind, they reflect the meticulous craftsmanship of an rtd temperature sensors manufacturer, steering the future toward a secure and sustainable energy landscape.

References

- Motor PT100 PT1000 Platinum Resistance Temperature Sensor– Detailed overview of motor temperature sensors for industrial applications

- RTD Temperature Sensors | Platinum Resistance– Comprehensive catalog of RTD platinum resistance temperature sensors

- Accurate Temperature Measurement– Insights into achieving precise temperature measurements using advanced sensors

- Series A, Miniature RTD– Instruction manual detailing the use and safety of Series A RTD sensors

- ENERGY RESEARCH AND DEVELOPMENT DIVISION– Report discussing the role of RTD sensors in energy research and development