In the ever-evolving landscape of industrial technology, thermocouple manufacturers play a pivotal role in providing essential temperature measurement tools. Among these tools, K-Type and E-Type thermocouple sensors have emerged as indispensable components in various sectors. These sensors are renowned for their precision and reliability, making them crucial for industries that demand accurate temperature readings. The integration of a spring-loaded mechanism in these sensors ensures consistent contact, which is vital for maintaining accuracy in challenging environments. Their robust construction enables them to withstand harsh conditions, guaranteeing long-term durability. As thermocouple suppliers continue to innovate, these sensors are becoming increasingly versatile, compatible with a wide array of industrial applications, and incorporating advanced technology for enhanced performance.

Table of contents:

Applications of Thermocouple Temperature Sensors in Diverse Industries

The Benefits of Using Spring-Loaded Thermocouple Probes for Consistency

How Advanced Thermocouple Sensors Meet High Industry Standards

Incorporating Thermocouple Sensors into Complex Industrial Systems

Applications of Thermocouple Temperature Sensors in Diverse Industries

Thermocouple temperature sensors are integral to numerous industries, ranging from plastics and injection molding to aerospace and automotive sectors. In injection molding machines, K-Type and E-Type sensors are particularly valuable due to their ability to deliver precise temperature measurements, which are crucial for producing high-quality products. Thermocouple manufacturers have developed these sensors to meet the rigorous demands of such applications, ensuring that they can handle the high temperatures and pressures involved. Additionally, these sensors are employed in the aerospace industry, where accurate temperature readings are essential for ensuring the safety and performance of aircraft components. Thermocouple suppliers also cater to the automotive industry, providing sensors that help optimize engine performance and emissions control, thereby enhancing vehicle efficiency and sustainability.

The Benefits of Using Spring-Loaded Thermocouple Probes for Consistency

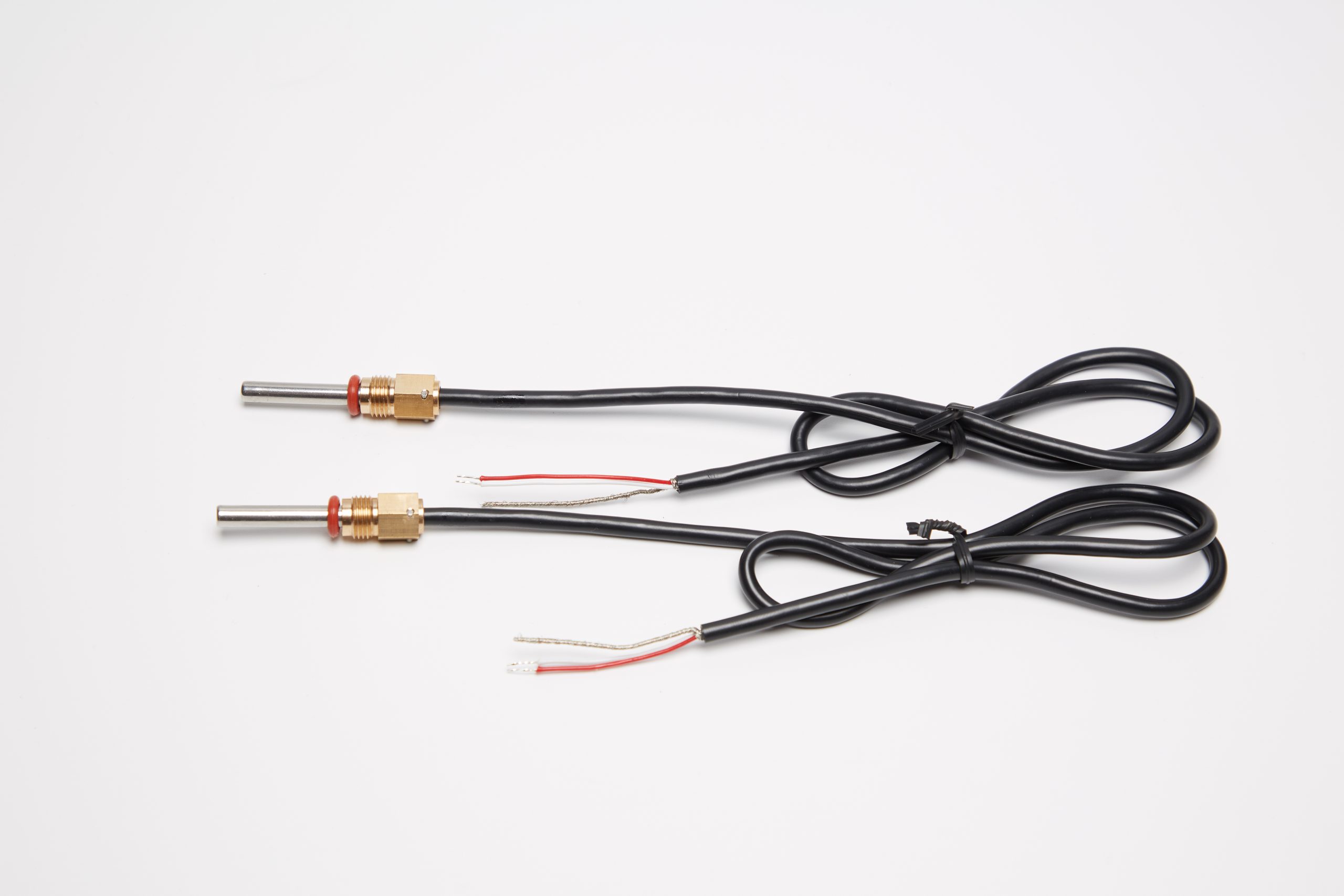

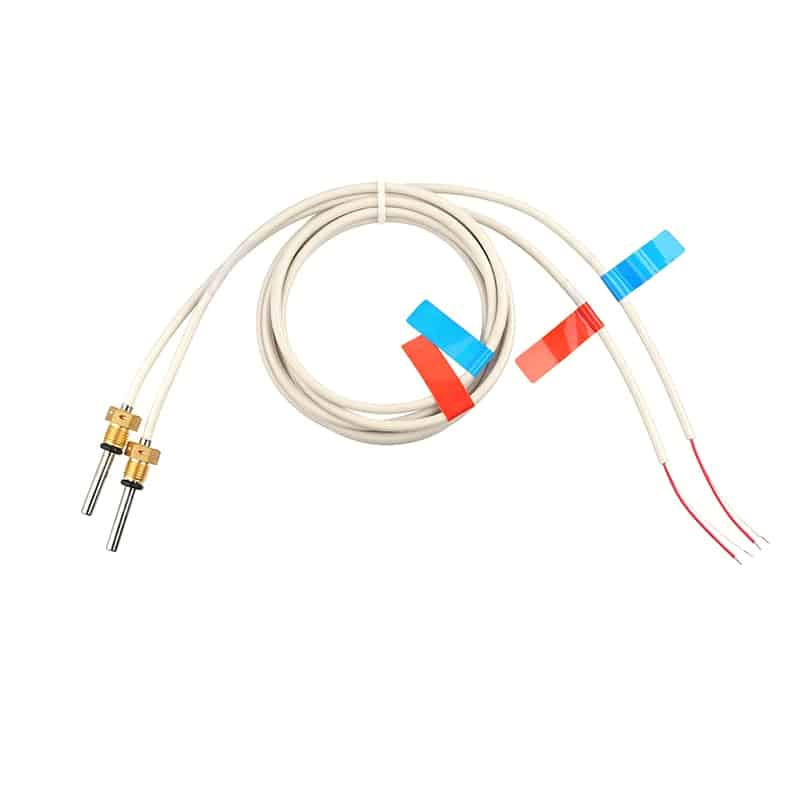

Spring-loaded thermocouple probes are designed to maintain firm contact with the measurement surface, ensuring consistent and reliable readings. This feature is particularly advantageous in environments where vibrations or movements may affect sensor placement. Thermocouple manufacturers have recognized the importance of this design, integrating it into their products to enhance performance and accuracy. The spring-loaded mechanism compensates for any surface irregularities, providing stable temperature measurements that are crucial for process control and quality assurance. Thermocouple suppliers emphasize the importance of this feature in industries where precision is paramount, such as injection molding and high-temperature processing. By ensuring consistent contact, these probes contribute to improved product quality and reduced downtime, offering significant benefits to industrial operations.

How Advanced Thermocouple Sensors Meet High Industry Standards

Advanced thermocouple sensors are engineered to meet stringent industry standards, ensuring they provide reliable and accurate temperature measurements. Thermocouple manufacturers employ cutting-edge technology and rigorous testing to guarantee their sensors perform optimally in demanding conditions. These sensors are often ISO-certified, reflecting their adherence to international quality standards. Thermocouple suppliers offer customized solutions to meet specific industry requirements, providing sensors that are tailored to particular applications. The use of high-quality materials and precision engineering ensures that these sensors can withstand extreme temperatures and pressures, making them suitable for a wide range of industrial environments. By maintaining high standards, thermocouple manufacturers ensure their sensors contribute to improved safety, efficiency, and productivity across various sectors.

Incorporating Thermocouple Sensors into Complex Industrial Systems

Integrating thermocouple sensors into complex industrial systems requires careful consideration of various factors, including compatibility, accuracy, and reliability. Thermocouple manufacturers have developed sensors that can seamlessly integrate into existing systems, providing accurate temperature measurements that are essential for process control and optimization. Thermocouple suppliers offer technical support and customization services to ensure their sensors meet the specific needs of different industries. This includes providing sensors with specialized features, such as enhanced durability and resistance to environmental factors. By incorporating advanced technology and design, thermocouple sensors can operate effectively within complex systems, contributing to improved operational efficiency and product quality. As industries continue to evolve, thermocouple manufacturers are committed to developing innovative solutions that meet the growing demands of industrial applications.

In summary, K-Type and E-Type thermocouple sensors are vital components in today’s industrial landscape, offering precision and reliability across various sectors. Thermocouple manufacturers and suppliers play a crucial role in developing and providing these sensors, ensuring they meet high industry standards and are capable of performing in demanding environments. The spring-loaded design enhances consistency, while advanced technology ensures these sensors can integrate seamlessly into complex systems. As industries continue to advance, the versatility and durability of thermocouple sensors will remain essential, supporting the ongoing pursuit of efficiency and quality in industrial operations. The collaboration between thermocouple manufacturers and suppliers is key to driving innovation and meeting the evolving needs of diverse industries.