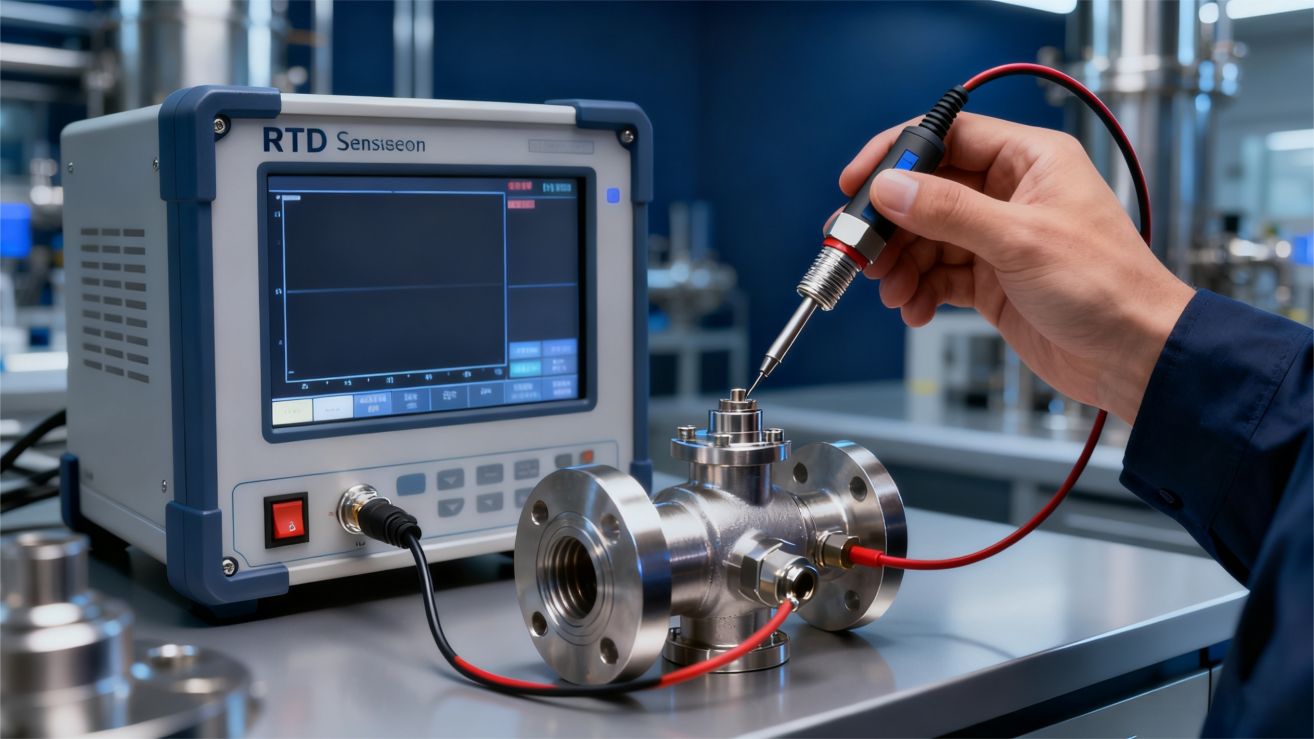

Introduction: RTD sensors ensure precision with diverse temperature ranges (-60℃ to +230℃) and long-term stability, crucial for industrial applications.

In today’s fast-paced industrial environments, precision in temperature measurement can often be the difference between success and operational setbacks. Yet, many workflows suffer from inefficiencies due to inconsistent or unreliable temperature sensor readings. RTD temperature sensors are engineered to bridge this gap, ensuring seamless performance and accuracy across various applications. When seeking solutions from rtd temperature sensors manufacturers, quality and precision should be paramount to uphold standards and optimize operational consistency.

Evaluation criteria for sourcing RTD temperature sensors in industrial applications

Selecting the right RTD temperature sensors requires careful consideration of the specific needs of industrial applications. A key factor in this decision-making process is accuracy. Sensors must deliver precise readings within defined tolerances and resistance classes, such as 1/3 Class B, Class A, and Class B. The sensors’ ability to perform across diverse temperature ranges, such as -60℃ to +230℃, is crucial for versatility. Additionally, insulation parameters like an insulation voltage of 1800VAC for 2 seconds and insulation resistance of ≥100MΩ at 500VDC ensure reliability during operations. RTD sensor manufacturers often provide insights on these characteristics to ensure sensors meet rigorous industrial standards. It’s also important to look for sensors crafted with durable materials such as stainless steel, which supports longevity and performance stability. When assessing an rtd temperature sensors manufacturer, considering the integration of such features can guide industry professionals toward choices that align with their application demands.

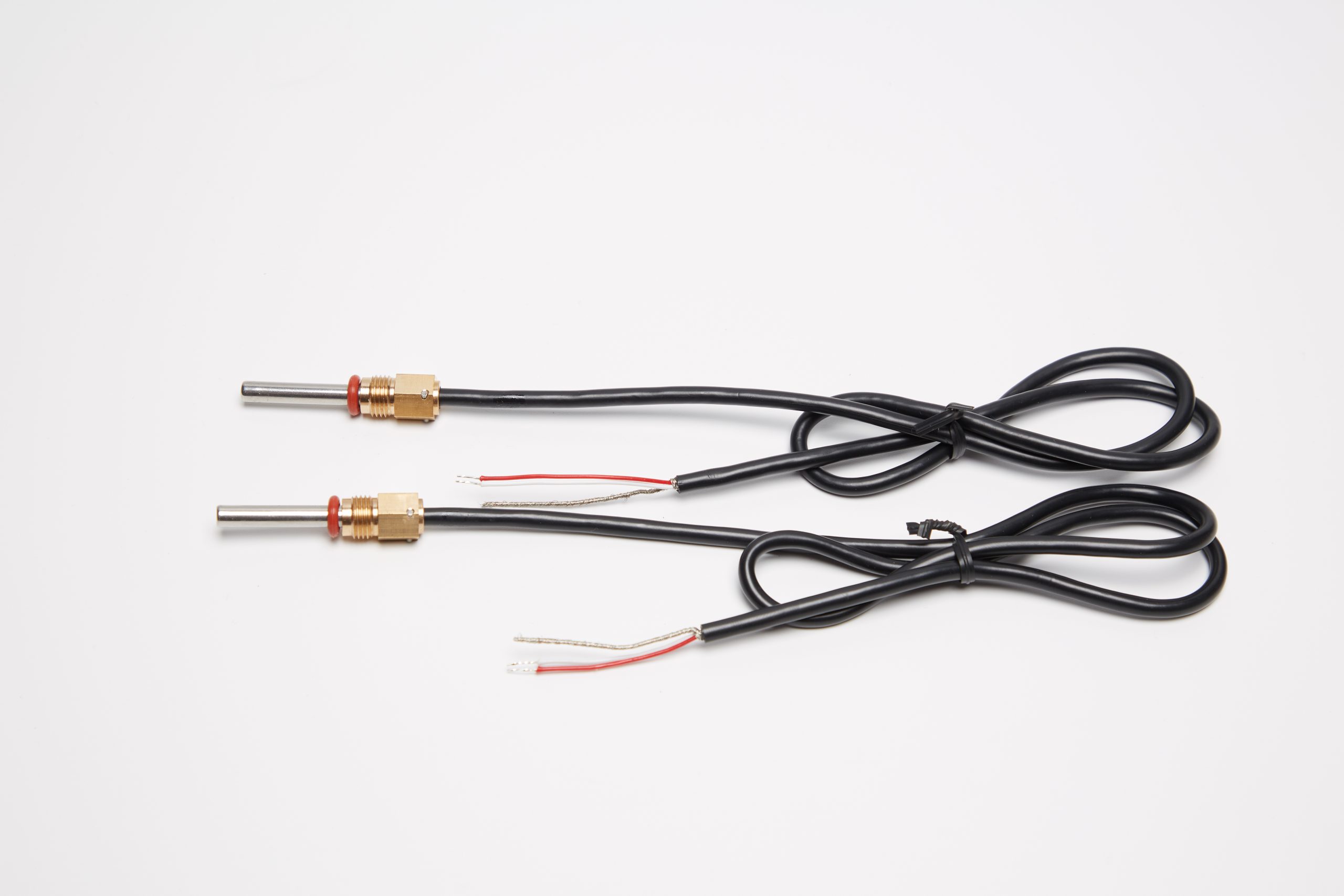

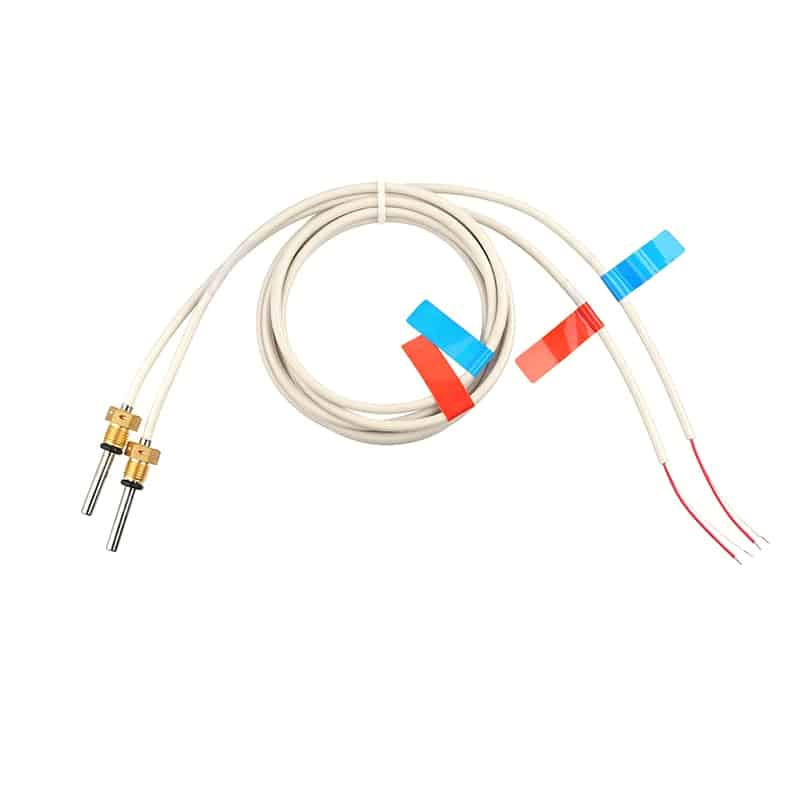

Customization options including wire specifications and signal outputs

In many industrial settings, customization is a significant factor influencing the choice of RTD sensors. Each environment may have specific requirements pertaining to wire specifications or signal outputs, which necessitates tailored solutions. RTD sensor manufacturers offer sensors with silver-plated Teflon wires, known for maintaining high-temperature accuracy, thus complementing the durable sensor packaging options like PTFE Teflon rubber. Another customization avenue is the communication modes, where options like two-wire and three-wire systems are available, impacting the signal outputs. Such flexibility allows users to modify signal pathways to enhance compatibility with existing systems, promoting seamless operation. Moreover, the customization extends to the variety in wire diameters and lengths, enabling modification to suit spatial constraints or installation challenges. An adaptable rtd temperature sensors manufacturer who prioritizes customization can significantly enhance operational efficiency by providing products that fit specific use-case requirements. Customization is not merely an enhancement but a necessity in diverse industrial applications, ensuring the technology fits seamlessly into existing frameworks.

Importance of long-term stability and certification in RTD sensor procurement

A vital aspect of RTD sensor procurement is the pursuit of long-term stability and rigorous certification. Long-term stability translates to consistent performance over extended operational periods, ensuring durations of up to 1000 hours yield negligible temperature deviations—to less than 0.04%. This stability is often a criterion prioritized by rtd temperature sensors manufacturers to guarantee their products’ reliability, critical in industries where precise temperature readings protect the integrity of processes, such as in electric vehicle motor overheating protection. Certification and adherence to strict industry standards further validate the quality of RTD sensors, cementing their role in environments requiring unwavering accuracy. Such certifications often highlight the sensor’s ability to deliver precision repeatedly. By choosing an rtd temperature sensors manufacturer recognized for their commitment to stability and certification, industry professionals align with robust performance expectations, helping to mitigate potential disruptions and safeguard the seamless functionality of vital temperature-dependent systems.

RTD temperature sensors crafted with high-quality materials and designed for customization represent a keystone in optimizing industrial workflows. Exploring the offerings from premier rtd sensor manufacturers reveals much about their suitability and reliability. With advancements in design, such as insulation resistance and the availability of varied communication modes, RTD sensors remain superior tools in the realm of temperature management. Embracing these features and characteristics ensures that operations within the most demanding applications can continue to run smoothly and accurately, securing the future of temperature-based precision.

References

- 2 Wire 3 Wire RTD Platinum Resistance Temperature Sensor For New Energy– High-precision RTD sensors with customizable wire configurations for new energy applications.

- RTD and Thermocouple Selection and Location for Optimal Control– Practical recommendations for sensor selection and placement to improve temperature loop performance.

- How to Choose the Right Thermocouple or RTD Sensor (Part 2)– Factors to consider when choosing the right RTD or thermocouple for a measuring point in a process.

- Choosing and Using a Temperature Sensor– Overview of temperature sensor types and factors to consider for specific applications.

- Temperature Sensor Buying Guide– Guide on selecting temperature sensors, including RTDs, for various industrial applications.