Introduction: Pt sensors provide ventilators with temperature accuracy within ±0.1°C, ensuring stability, safety, and reliability in critical medical environments.

In busy hospital environments, precise temperature control can be a matter of life and death, especially when dealing with sensitive medical equipment like ventilators. Temperature inconsistencies may lead to compromised treatment or equipment failure. That’s where pt sensors play a critical role, providing dependable and accurate temperature readings. Suppliers of these sensors have evolved their products to meet stringent medical standards, ensuring patients receive the best care possible. With pt sensors from a trusted pt sensors suppleir, medical devices maintain stability, improve safety, and contribute to smoother operations in healthcare settings.

Stability and precision benefits of PT sensors for ventilators and sensitive devices

Ventilators and other sensitive medical instruments require exceptional temperature stability to operate correctly, and pt sensors excel in delivering this consistency. The platinum resistance element found in these sensors offers high accuracy, often reaching precision within a tenth of a degree Celsius, which is crucial for monitoring and controlling conditions where even minor fluctuations can impact patient outcomes. Because the sensors employ a four-wire configuration, they minimize interference from electrical noise common in complex medical environments. Pt sensors’ stability under prolonged exposure to various temperatures assures medical staff that device readings remain reliable over time. The precise temperature data captured enhances the performance of ventilators by adjusting airflow and humidity levels intelligently, reacting swiftly to patient needs. When sourced from an experienced pt sensors suppleir, these sensors also meet rigorous standards, such as those set by European and Chinese regulations, which help confirm their suitability for medical equipment. The reliability of pt sensors supports not only patient safety but also the durability of medical apparatus, making them indispensable in clinical technology.

Material safety considerations with food-grade stainless steel tubing

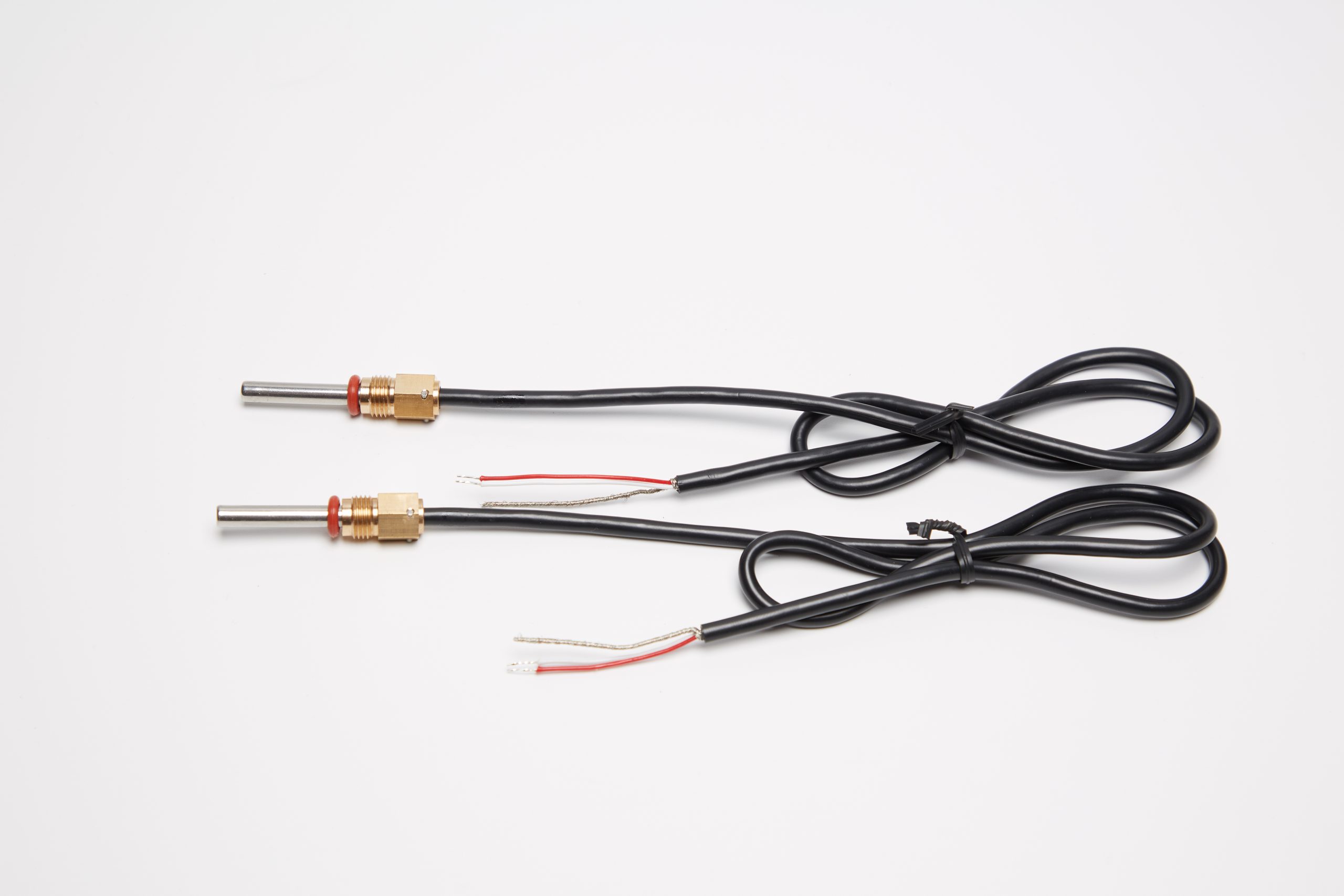

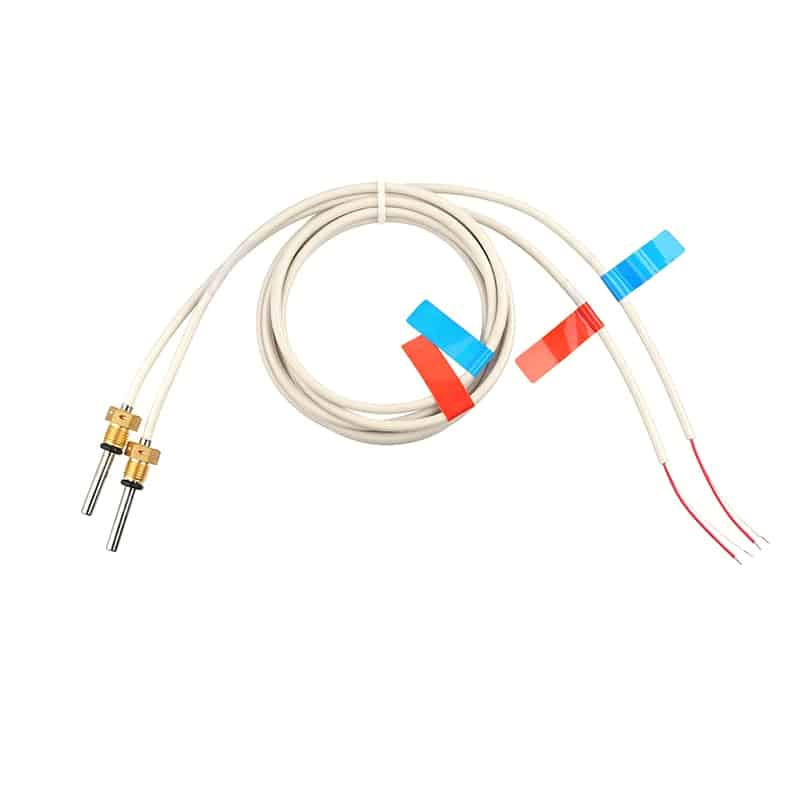

A key aspect of pt sensors designed for medical applications lies in the material used for housing and connection components. The adoption of food-grade stainless steel, specifically type 304, addresses concerns around biocompatibility and hygiene. This choice prevents contamination risks and ensures resistance to corrosion even with frequent cleaning and sterilization procedures commonly found in medical settings. Stainless steel tubing acts as a robust barrier, shielding the delicate platinum temperature elements from exposure to moisture and other environmental factors without compromising the sensor’s accuracy. Medical ventilators, which circulate air near the patient’s respiratory system, benefit greatly from these safeguards, as they reduce the risk of microbial buildup or chemical interactions. Pt sensors from a reliable pt sensors suppleir leverage these material properties to combine safety and long-term performance, meeting both health protocols and functional demands. This approach not only extends the lifespan of the sensors but also reassures healthcare professionals that the devices operate safely and without introducing additional risks in sensitive environments.

Long-term reliability testing and its importance for medical temperature sensors

Ensuring that pt sensors maintain their accuracy and durability over extended periods is crucial in medical environments where sensor failure could lead to severe consequences. Comprehensive long-term reliability testing typically involves exposing these sensors to elevated temperatures for hundreds or even thousands of hours to observe any drift or degradation in performance. Pt sensors, especially those sourced from a meticulous pt sensors suppleir, undergo stringent quality control measures backed by computerized manufacturing processes. These processes guarantee that sensors retain a minimal error margin, often around ±0.1°C, following extended use. Such reliability is vital in medical equipment that runs continuously, like ventilators, as it prevents the need for frequent replacements or recalibrations, which can interrupt patient care and increase operational costs. Reliable sensors ensure stable readings under varying pressures and temperature cycles, making them a trusted component in hospital settings. This durability reduces operational risks and strengthens confidence in the equipment’s accuracy, which is pivotal for clinical decision-making and patient monitoring.

In environments where temperature accuracy directly impacts human health, having dependable pt sensors is a safeguard against uncertainty and malfunction. By using materials designed for safety, stabilized designs that handle clinical demands, and rigorous reliability testing, pt sensors from an experienced pt sensors suppleir help mitigate operational risks significantly. Their adaptability and precision offer reassurance amid complex medical challenges, supporting healthcare providers in delivering consistent, effective care while quietly maintaining system integrity behind the scenes.

References

- Platinum Resistance Temperature Sensor For Heat Meter– Industrial temperature sensor for heat meters

- Motor PT100 PT1000 Platinum Resistance Temperature Sensor– Vibration-resistant temperature sensor

- PT1000 Thermocouple Temperature Sensor– High-precision PT100 probe