Fluid Temperature Sensor: Enhancing Precision Measurement in Industrial Applications

Abstract:

This article explores the significance of fluid temperature sensors in industrial applications. It delves into their functionality, benefits, and the impact they can have on enhancing precision measurement. From automotive to pharmaceutical industries, accurate monitoring of fluid temperatures is crucial for ensuring optimal performance and safety. In this article, we will discuss the working principles, advantages, and key considerations when selecting a fluid temperature sensor. Let’s dive in and explore how these sensors play a vital role in various industries.

Table of Contents:

1. Introduction

2. Understanding Fluid Temperature Sensors

3. Key Benefits of Fluid Temperature Sensors

4. Applications in Automotive Industry

5. Ensuring Process Efficiency in Pharmaceuticals

6. Selecting the Right Fluid Temperature Sensor

7. Conclusion

1. Introduction:

In today’s rapidly evolving industrial landscape, precise temperature measurement is indispensable. Fluid temperature sensors have emerged as critical components in various sectors, ensuring reliable and accurate readings. These sensors enable efficient control and monitoring of fluid temperatures, ultimately optimizing performance and safety across industries. This article aims to provide insights into the functionalities and benefits of fluid temperature sensors, shedding light on their essential role in industrial settings.

2. Understanding Fluid Temperature Sensors:

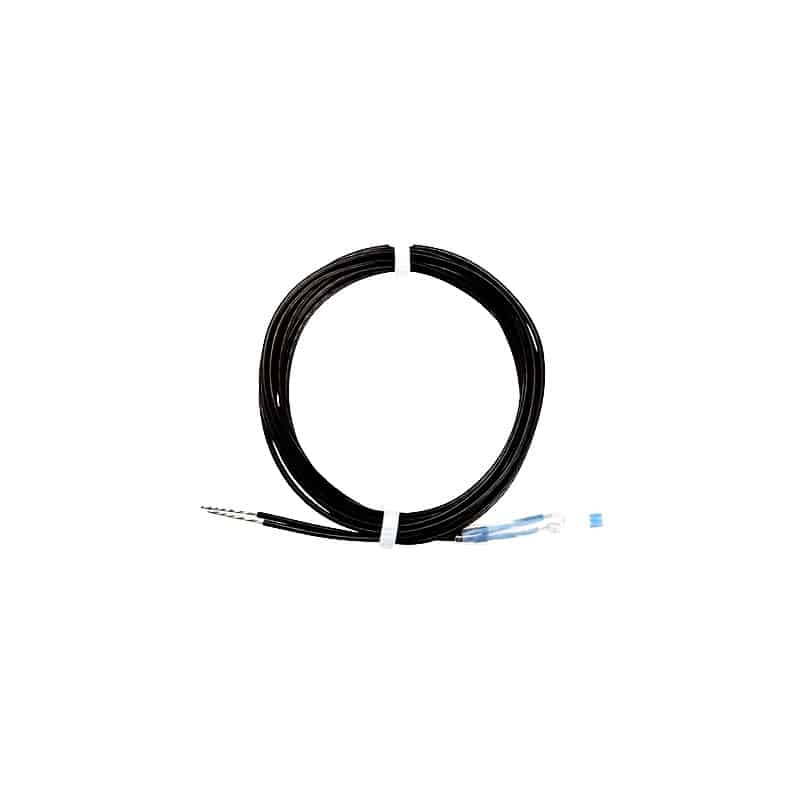

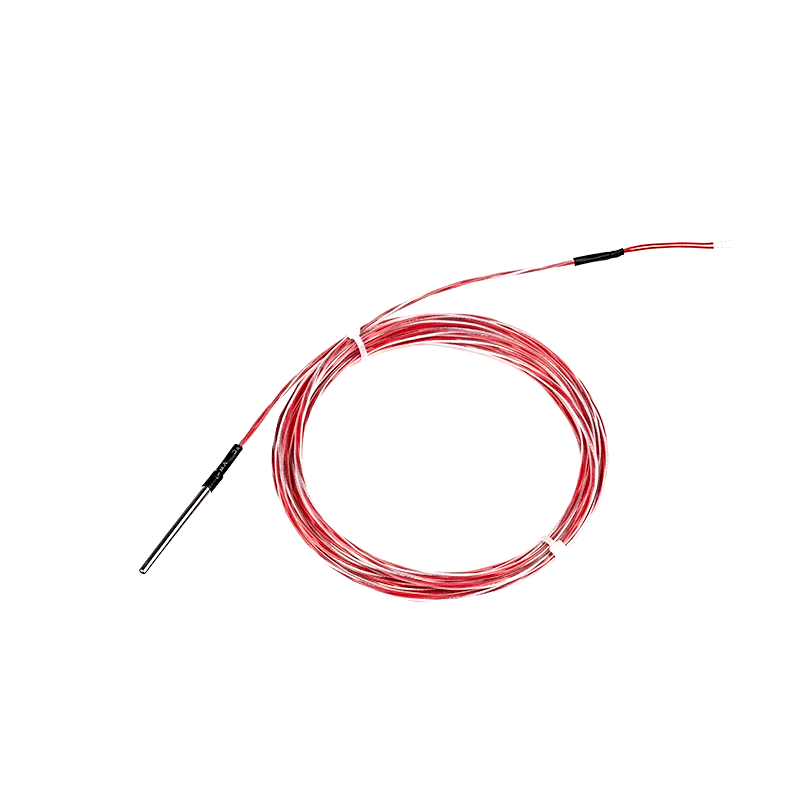

Fluid temperature sensors are sophisticated devices designed to measure and monitor the temperature of liquids, gases, or other media. They employ advanced technologies such as thermocouples, resistance temperature detectors (RTDs), and thermistors to detect and convert temperature variations into electrical signals. These signals are then processed and utilized for precise temperature measurement. Fluid temperature sensors come in various forms, including immersion sensors, insertion sensors, surface sensors, and more, catering to diverse application requirements.

3. Key Benefits of Fluid Temperature Sensors:

Fluid temperature sensors offer several notable advantages that contribute to enhanced industrial operations. Firstly, they provide real-time temperature data, enabling swift detection of potential issues or abnormalities. This proactive approach helps prevent equipment failures, reduces downtime, and improves overall efficiency. Moreover, these sensors facilitate accurate temperature regulation, ensuring optimal performance and product quality. From process optimization to energy conservation, fluid temperature sensors offer substantial benefits to industries.

4. Applications in Automotive Industry:

The automotive sector heavily relies on fluid temperature sensors for critical functions. Engine coolant temperature sensors, for example, enable precise monitoring of coolant temperatures, preventing overheating, and safeguarding engine components. Transmission fluid temperature sensors play a crucial role in optimizing gear shifting and preventing excessive wear. Additionally, HVAC systems within vehicles employ fluid temperature sensors to regulate cabin temperatures effectively. The automotive industry greatly benefits from the reliability and accuracy of fluid temperature sensor technology.

5. Ensuring Process Efficiency in Pharmaceuticals:

In the pharmaceutical industry, maintaining precise temperature conditions is paramount. Temperature-sensitive substances and processes necessitate vigilant monitoring to ensure product integrity and patient safety. Fluid temperature sensors play a vital role in this regard, enabling continuous monitoring and control of critical environments such as storage facilities, laboratories, and manufacturing areas. These sensors provide the necessary data to uphold strict regulatory compliance, guaranteeing the efficacy of pharmaceutical operations.

6. Selecting the Right Fluid Temperature Sensor:

Choosing the appropriate fluid temperature sensor requires careful consideration of various factors. Factors such as the temperature range, media compatibility, response time, accuracy requirements, and environment conditions must be thoroughly assessed. Each application may demand a specific type of sensor, be it a thermocouple, RTD, or thermistor. Consulting with experts and understanding the unique requirements of the industrial process is crucial to selecting the right sensor for optimal results.

7. Conclusion:

Fluid temperature sensors serve as indispensable tools in achieving precision measurement and control across diverse industrial domains. With their ability to provide real-time temperature data, ensure optimal performance, and enhance safety, these sensors are integral components in numerous applications. From the automotive sector to pharmaceuticals, accurate temperature monitoring is vital for smooth operations. By selecting the right fluid temperature sensor and leveraging its benefits, industries can optimize efficiency, productivity, and overall performance. Embrace the power of fluid temperature sensors and unlock the potential for excellence in your industrial processes.

Keywords: fluid temperature sensor, precision measurement, industrial applications, sensor functionality, benefits, automotive industry, pharmaceutical industry, sensor selection, temperature regulation, monitoring and control.

The Impact of Temperature Sensors on Modern Energy Solutions

In the rapidly evolving world of energy solutions, temperature sensors play a crucial role in ensuring efficiency and safety. These sophisticated devices are integral to the functionality of various systems,