Introduction: RTD sensor manufacturers provide customizable solutions with precision from -60℃ to +230℃, enhancing operational efficiency and reliability.

As the days shorten and the air turns crisp, industries gear up for increased energy demands. In such scenarios, precision in temperature monitoring is paramount, particularly for businesses relying on rtd sensor manufacturers. These intricately designed sensors offer reliability and accuracy precisely where it’s needed. Whether it’s monitoring electric vehicle motors for overheating or ensuring the efficiency of battery aging equipment, the role of rtd temperature sensors manufacturer becomes increasingly critical in maintaining operational standards during peak seasonal transitions.

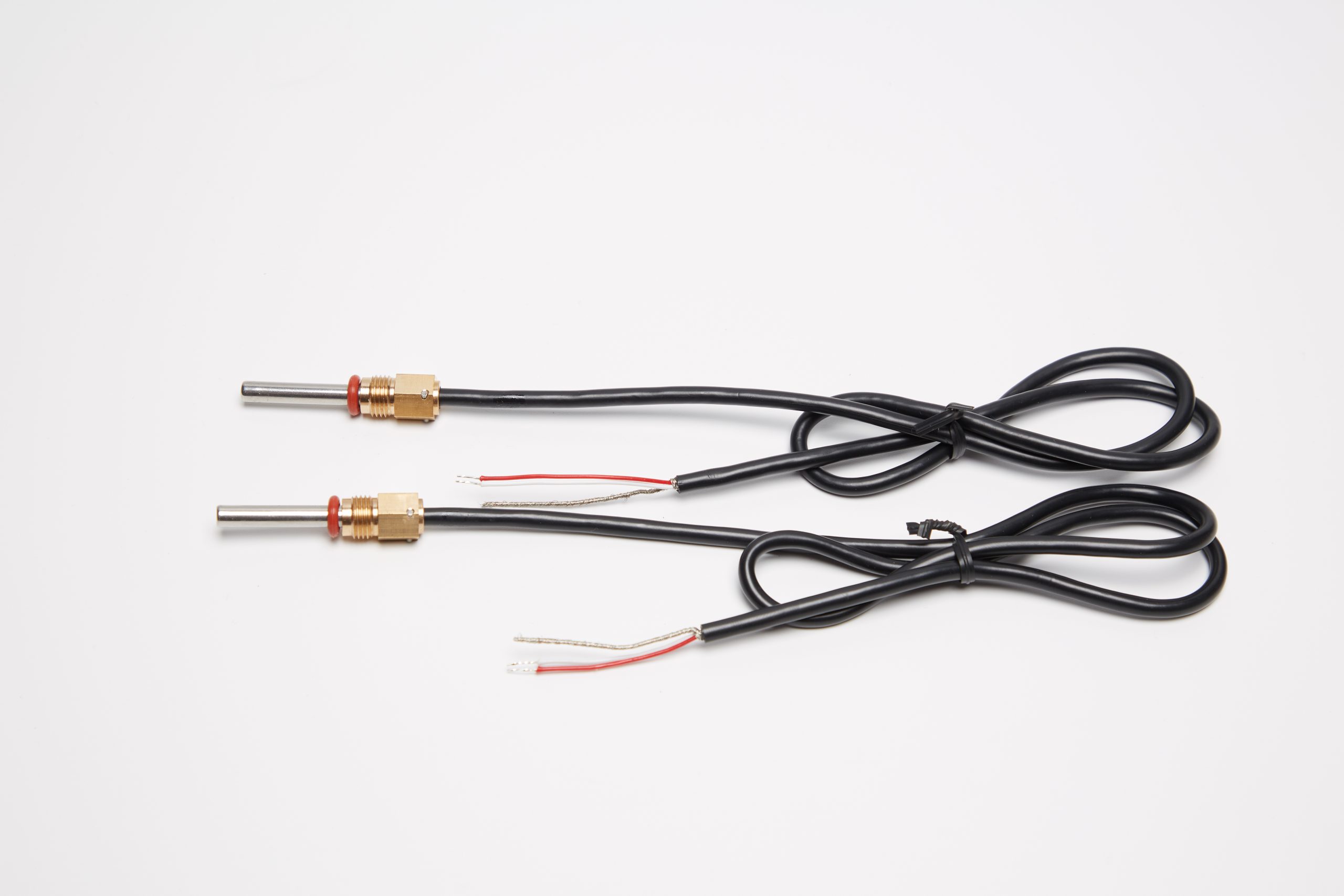

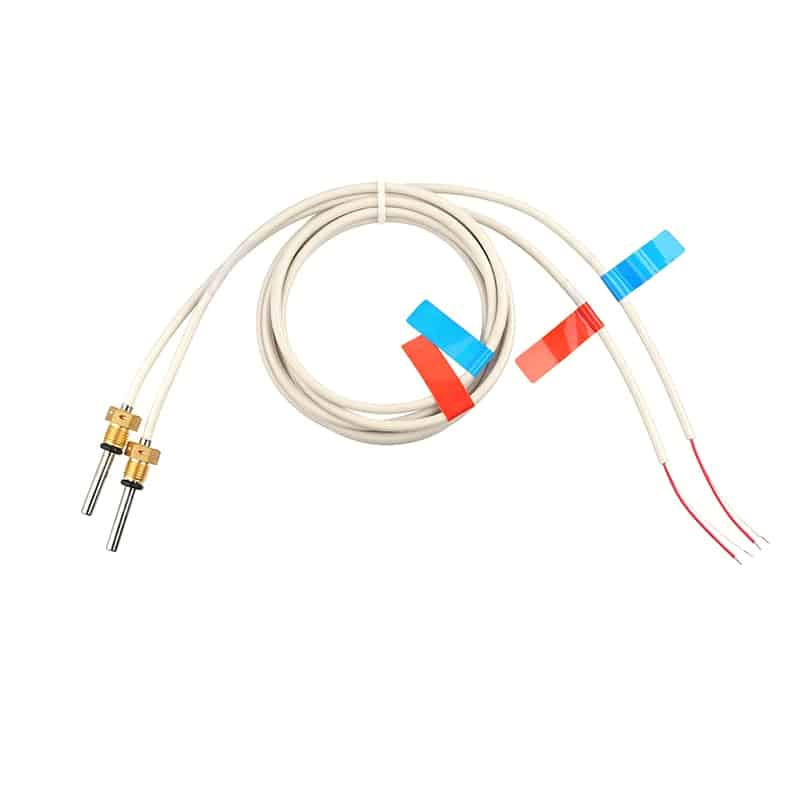

Flexibility in designing RTD sensors including wire length and diameter customization

A defining advantage of partnering with renowned rtd sensor manufacturers lies in the ability to tailor product features to specific needs. For industries with niche requirements, the customization of wire length and diameter in RTD temperature sensors is a game changer. The versatility in design ensures that sensors fit seamlessly into varied applications, no matter how unique. Utilizing materials like silver-plated Teflon wire housed in durable stainless steel or PTFE Teflon, these adaptations cater to diverse operational environments. From compact spaces requiring ultra-thin wiring to expansive setups that necessitate longer measurements, the customization options offer more than convenience—they ensure precision. This flexibility underscores the commitment from rtd temperature sensors manufacturers to provide solutions that seamlessly integrate into existing systems, enhancing not only functionality but also user confidence in the technology’s durability and performance.

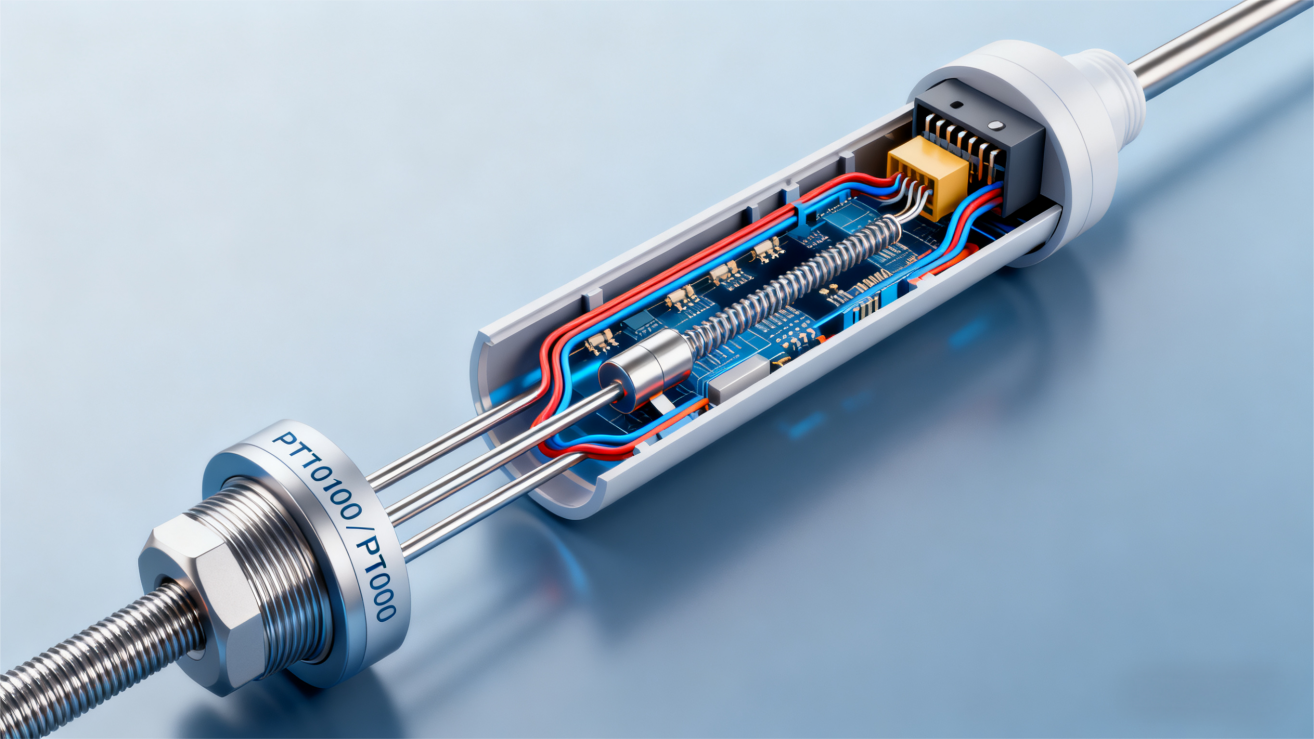

Combining platinum resistance elements with optional NTC thermistor outputs

At the heart of efficient temperature monitoring is accuracy, and rtd sensor manufacturers have perfected this with their platinum resistance elements. The precision of PT100 and PT1000 sensors has been the benchmark in achieving nearly linear temperature measurement. Yet, modern demands have inspired additional innovations. By integrating optional NTC thermistor outputs, these sensors offer additional adaptability, allowing users to select the ideal configuration suited to their application’s specific requirements. This combination not only increases the sensor’s capability to handle varying temperature ranges, from -60℃ to +230℃, but also offers enhanced stability and interchangeability. This innovation is a testament to rtd temperature sensors manufacturers’ dedication to advancing technology that meets evolving industrial demands. Industries revel in the confidence that comes with knowing every temperature shift is accurately captured, thereby protecting vital systems and prolonging equipment life through meticulous monitoring.

Supplier capabilities for supporting technical needs and collaborative development

When choosing partners for sensor development, the best rtd sensor manufacturers distinguish themselves through their robust support and collaborative approach. They recognize that temperature monitoring solutions must evolve alongside the industries they serve. These manufacturers offer more than products; they offer partnerships rooted in technical excellence and cooperative development. By providing specialized support, they assist clients in overcoming technical challenges and drive innovation. For instance, Starlightsensors exemplifies this with their commitment to quality and collaborative project development, ensuring each sensor is a custom fit for its intended application. This dedication results in rtd temperature sensors manufacturer establishing long-term relationships built on trust and mutual progress. Industries benefit from this synergy with enhanced operational efficiencies and reliable temperature monitoring solutions that are integral to their growth and sustainability. These partnerships with experienced manufacturers help enterprises navigate complexities with the assurance of receiving consistent quality and unwavering support.

In an ever-evolving technological landscape, rtd temperature sensors manufacturers play a crucial role in shaping the future of precision and reliability. Their commitment to customization, integration of advanced elements, and focus on collaborative development is setting new industry standards. As energy demands grow and industries seek to optimize efficiency, the strategic choice of working with trusted rtd sensor manufacturers becomes paramount. These manufacturers not only deliver durable, customized sensor solutions but also provide a pillar of support and innovation that enterprises can rely on. With a multitude of configurations available, from wire lengths to sensor outputs, they cater to diverse applications and evolving industrial needs. By aligning technical capabilities with market demands, manufacturers ensure their sensors continue to fit seamlessly into both current and emerging technologies, cementing their relevance in the industrial landscape for years to come.

References

- PT100, PT200, PT1000 Measure Instruments Platinum Resistance Temperature Sensor– High-accuracy RTD sensors with customizable features for diverse applications.

- Motor PT100 PT1000 Platinum Resistance Temperature Sensor– Specialized RTD sensors designed for precise motor temperature monitoring.

- High-Precision Thermocouple Temperature Sensor– Thermocouple sensors offering exceptional accuracy for industrial applications.

- ENERGY RESEARCH AND DEVELOPMENT DIVISION– Report discussing the role of RTD sensors in energy research and developmentsensors.

- Comparison of Thermocouple vs. RTD Sensors– In-depth analysis of thermocouple and RTD sensors for process control applications.