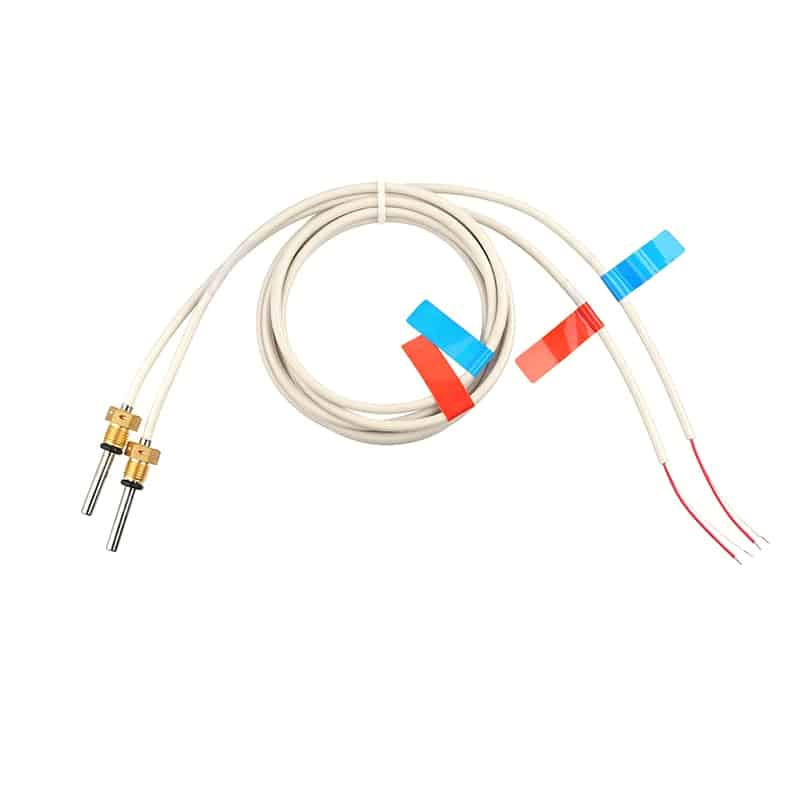

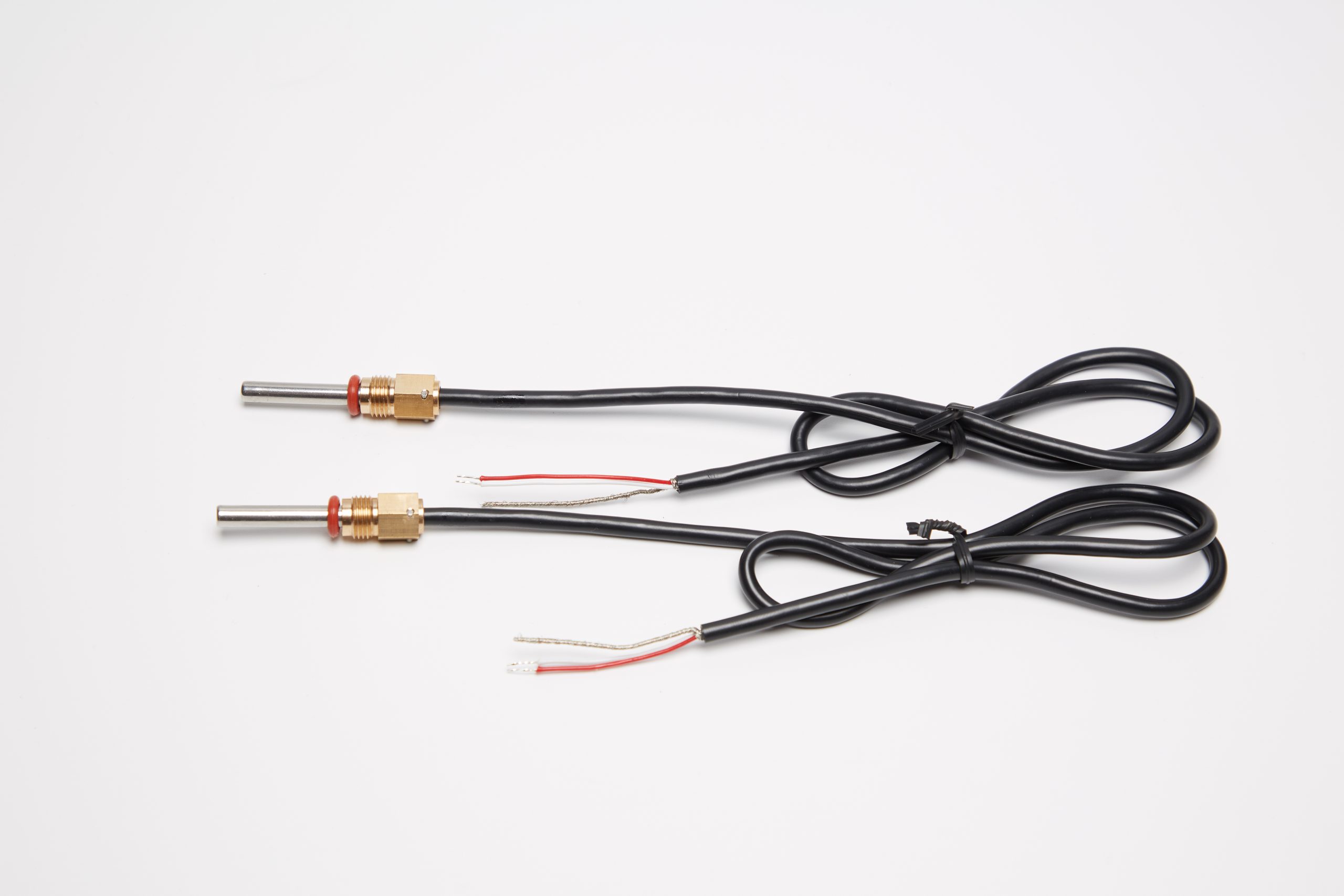

What Makes PT Sensors Manufacturer Solutions Stand Out in Heat Meter Applications

Introduction: PT sensors for heat meters offer ±0.1°C accuracy, customizable designs, automated quality control, and compliance with CJ 128-2007 and EN 1434 standards for reliable thermal measurement. In a bustling energy monitoring facility, technicians rely on precise instruments every day — especially when it comes to tracking heat consumption accurately. PT sensors play a pivotal role in these systems, translating subtle temperature variations into data that informs billing and efficiency decisions. For those engaged in heat meter applications, having a pt sensors suppleir offering not only precision but also reliability and tailored solutions can make a significant difference. These sensors