Introduction: PT sensors for heat meters offer ±0.1°C accuracy, customizable designs, automated quality control, and compliance with CJ 128-2007 and EN 1434 standards for reliable thermal measurement.

In a bustling energy monitoring facility, technicians rely on precise instruments every day — especially when it comes to tracking heat consumption accurately. PT sensors play a pivotal role in these systems, translating subtle temperature variations into data that informs billing and efficiency decisions. For those engaged in heat meter applications, having a pt sensors suppleir offering not only precision but also reliability and tailored solutions can make a significant difference. These sensors quietly govern the accuracy of thermal readings in complex setups, ensuring smooth operations and trustworthy evaluations.

Customization options and design features tailored to user needs

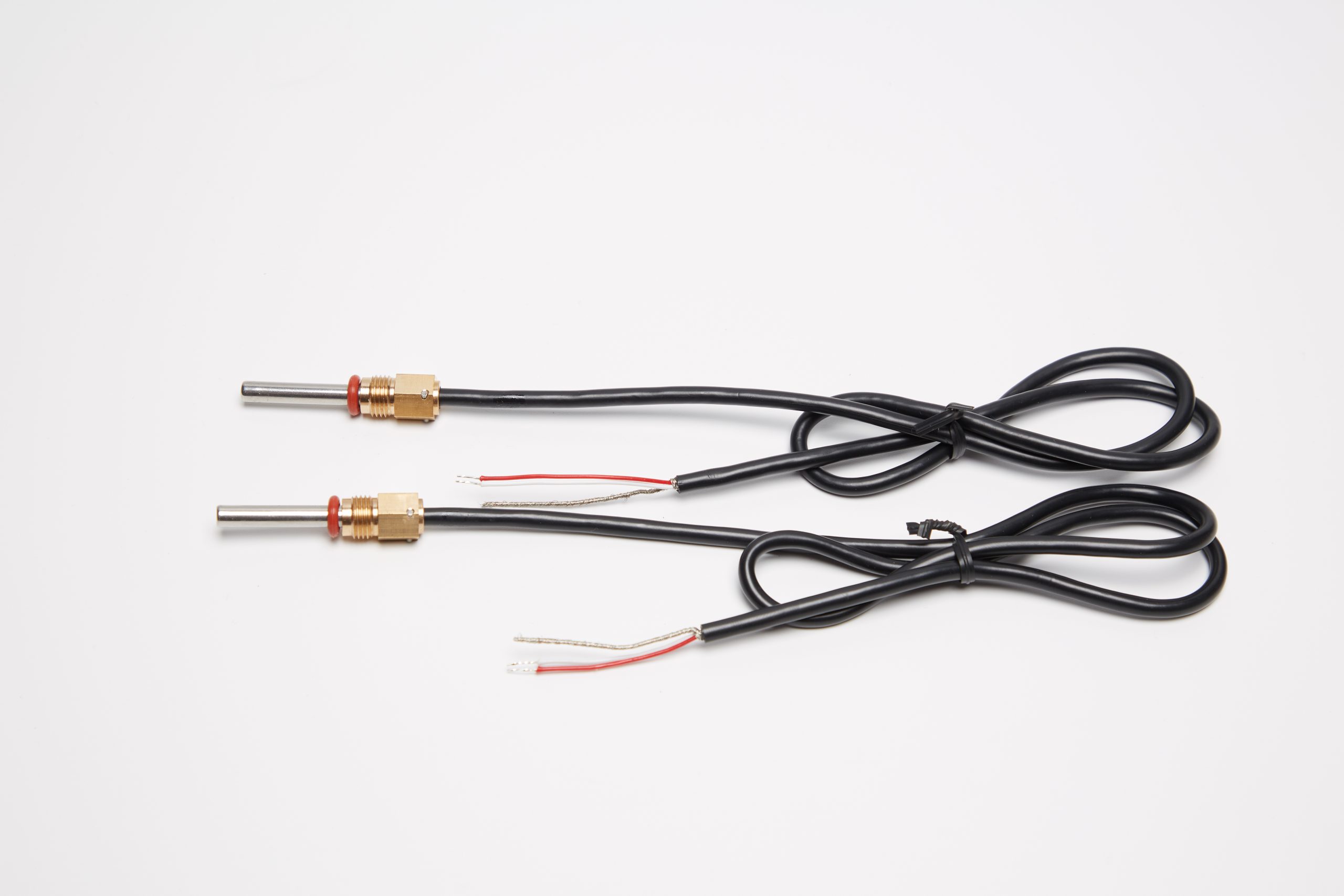

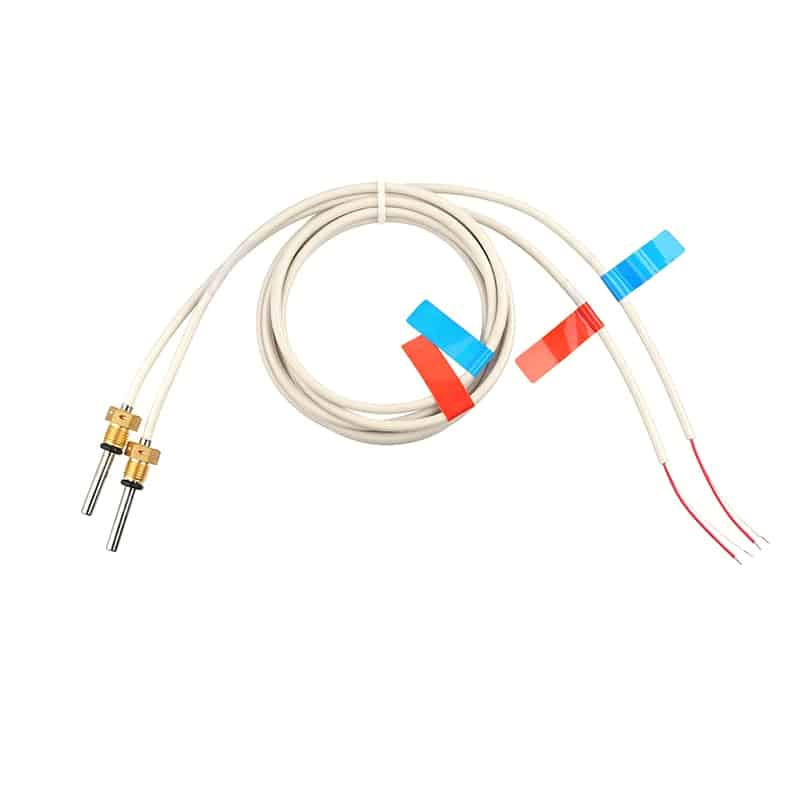

The world of heat measurement demands sensors that move beyond generic forms to address specific operational environments. PT sensors suppliers increasingly recognize the importance of customizable features, enabling users to select configurations that align with their precise requirements. For example, Starlightsensors delivers platinum resistance temperature sensors enclosed within 304 food-grade stainless steel tubes, a choice that balances durability with safety in a variety of settings. The design includes a movable copper nut connection, adapting to installation constraints without compromising integrity. Customization options also extend to probe lengths, wiring configurations, and resistance coefficients, allowing engineers to harmonize sensor characteristics with the unique demands of each heat meter system. A pt sensors suppleir that invests in this kind of adaptability naturally supports better integration, minimizing errors related to mismatches or poor fit. By focusing on patient understanding of the environments these sensors operate within, manufacturers create solutions that merge form with function, enhancing overall user experience. The familiar red and blue coding for upper and lower water pairing, respectively, reflects a thoughtful approach to intuitive design, preventing common installation errors. This attention to detail exemplifies how design tailored to user needs not only elevates accuracy but also operation efficiency in real-world applications.

Automated detection and pairing technology for improved sensor accuracy

Reaching consistently high precision in heat measurement systems requires more than just quality components; it demands intelligent assembly and verification processes. Many pt sensors suppliers integrate automated detection and pairing technologies into their manufacturing workflows to maintain stringent accuracy standards. Such automation ensures that each sensor’s temperature probes reach error margins within ±0.1°C, a critical threshold for sensitive heat meter applications. By employing computer-controlled systems, the matching of resistance values and probe pairs becomes systematic and repeatable, eliminating human error and reducing variability between batches. This process strengthens confidence in sensor data, especially when sensors operate under varying temperatures and pressures — up to 105°C and 16 bar in some models. The ability to detect subtle deviations early in production safeguards end users from receiving inaccurate components that might undermine system reliability. Additionally, this approach lends itself well to the mass customization trends seen in temperature sensing, where tailored sensors still benefit from consistent quality control. For customers who require top-tier measurement stability over extended periods, having a pt sensors suppleir that implements automated pairing technology signifies a commitment to delivering sensors that meet rigorous performance expectations without compromise.

Compliance with national and European standards in temperature sensor production

Navigating regulatory landscapes is critical when deploying temperature sensors in sensitive industrial and commercial contexts. PT sensors suppliers that demonstrate adherence to recognized standards deliver additional assurance of quality and safety to their clients. For instance, compliance with Chinese standard CJ 128-2007 alongside European standard EN 1434 offers a dual-layer validation that aligns with both regional and international expectations for heat meter components. Such certifications reflect that sensors meet established criteria for temperature accuracy, stability, and durability, buffer crucial for trust in billing environments and equipment longevity. Meeting these standards is not merely about paperwork but involves rigorous testing and adherence to production protocols, often supported by ISO certifications like ISO9001 or ISO14001. This comprehensive quality management ensures every sensor maintains a stable temperature coefficient of resistance and resists degradation even after prolonged exposure to high heat. For industries ranging from energy monitoring to medical ventilation systems, these credentials simplify compliance with broader regulatory demands while safeguarding operational consistency. Collaborating with a pt sensors suppleir that upholds these frameworks signals a dedication to producing sensors which are both reliable and legally sound for deployment across diverse sectors.

Stepping back into the realm where data accuracy impacts critical decisions highlights the quiet strength of a well-made temperature sensor. The careful attention to adaptable designs, the reliability ensured through automated quality controls, and the trustworthiness guaranteed by national and international compliance standards all underscore what distinguishes a thoughtful pt sensors supplier. Choosing components from a manufacturer that understands these demands naturally supports systems that operate with confidence and clarity. As technology and necessities evolve, these sensors remain pillars of dependable measurement, representing a steady presence in the shifting landscapes of heat metering and beyond.

References

- Platinum Resistance Temperature Sensor For Heat Meter– Heat meter sensor with ±0.1°C accuracy

- PT100, PT200, PT1000 Measure Instruments Platinum Resistance Temperature Sensor– High-temperature measuring accuracy

- Motor PT100 PT1000 Platinum Resistance Temperature Sensor– Vibration-resistant temperature sensor

- PT1000 Thermocouple Temperature Sensor– High-precision PT100 probe

- MF58D Thermistor– Reliable NTC temperature sensor