Introduction: Platinum resistance temperature sensors from reliable suppliers offer precise measurements with tolerances within tenths of a degree Celsius and withstand pressures up to sixteen bar.

In settings where precise temperature measurement can make a critical difference—from industrial heat meters to medical ventilators—having a reliable temperature sensor is non-negotiable. PT sensors from a reputable pt sensors suppleir step into this space with accuracy and durability. Imagine a technician ensuring a refrigeration system’s integrity in subzero environments or an engineer adjusting heat flow in a manufacturing line. These sensors, designed with rigorous standards, serve as the unseen guardians maintaining thermal balance and safety. Their consistent performance reflects the sophisticated processes behind them, supporting a wide array of critical applications.

Overview of sensor types including NTC thermistors and thermocouple sensors

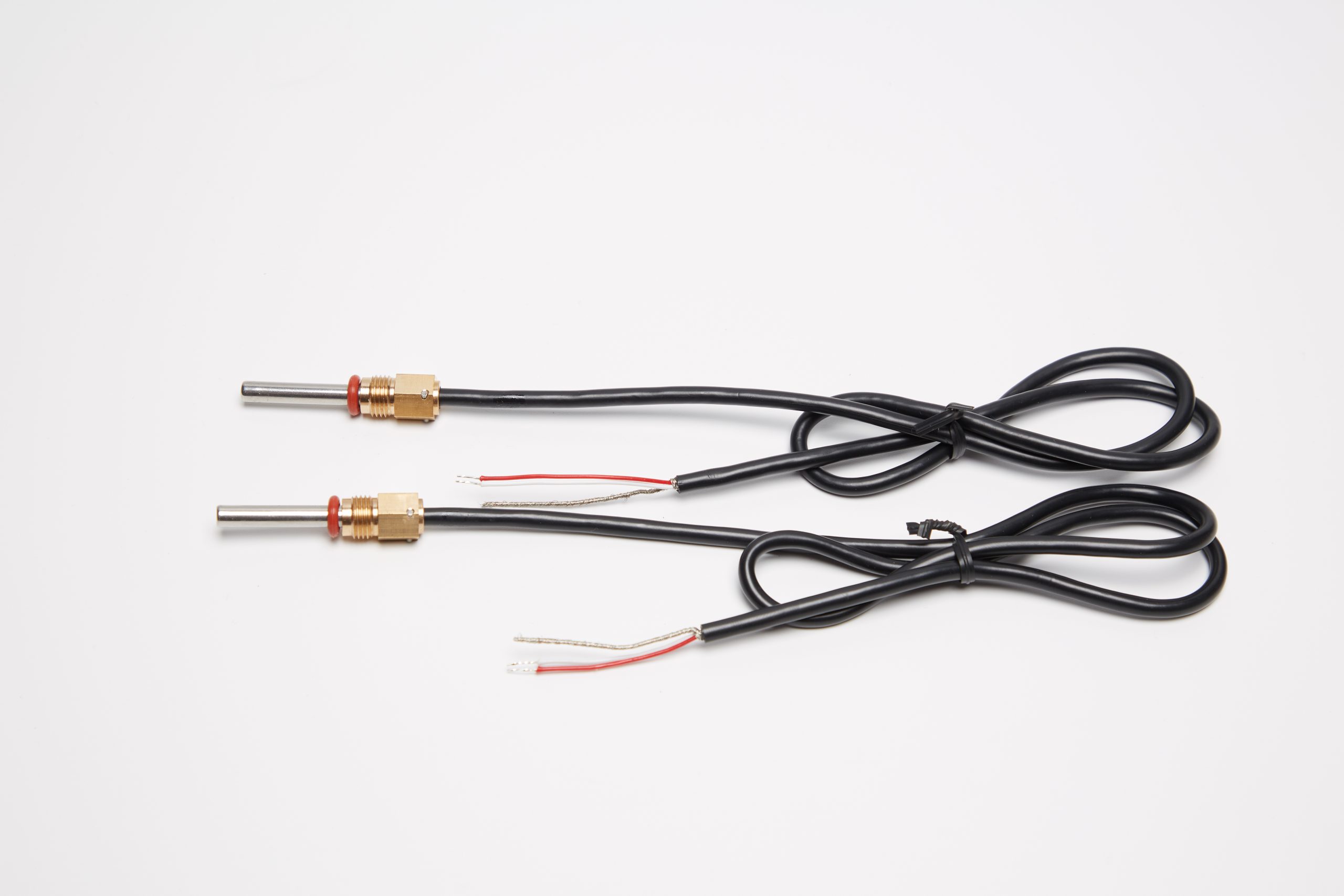

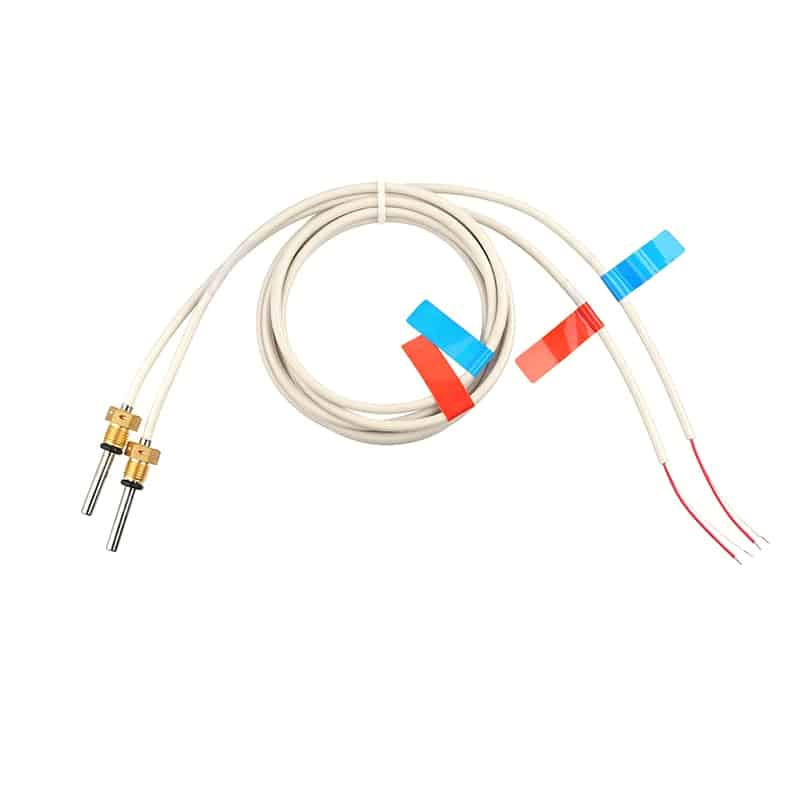

Temperature sensing technology offers several options, but among them, NTC thermistors, thermocouple sensors, and platinum resistance PT sensors stand out for their reliability and specialized uses. NTC thermistors respond sensitively to temperature changes by varying resistance, making them suitable for moderate precision needs such as consumer electronics or air conditioning systems. Thermocouple sensors, on the other hand, function across broad temperature ranges by measuring voltage differences generated at junctions between different metals, favored in high-temperature industrial applications. In comparison, PT sensors supplied by a reliable pt sensors suppleir exploit the stability of platinum resistance elements, particularly PT1000 configurations, delivering fine resolution and repeatability within tight error margins. Their design often includes features like food-grade stainless steel casings and color-coded probes to prevent installation errors, reflecting a blend of functional engineering and user-centric safety considerations. This portfolio of options enables businesses to match sensor characteristics to specific environmental and operational demands without sacrificing long-term accuracy or durability.

Use cases for Platinum Resistance Temperature Sensors versus other sensor technologies

The greatest strength of Platinum Resistance Temperature Sensors lies in their precision and stability under demanding conditions, setting them apart from other sensing technologies in scenarios where incremental inaccuracies could cascade into significant operational setbacks. Industries requiring exact thermal monitoring, like energy metering through heat meters, or temperature regulation in new energy vehicles, benefit from the refined measurements PT sensors provide, often holding tolerances within tenths of a degree Celsius. These sensors withstand pressures up to sixteen bar and sustain performance over prolonged exposure to temperatures nearing one hundred five degrees Celsius. While thermocouples handle extremes better and NTC thermistors respond swiftly to change, PT sensors strike a balance by excelling in environments with stable yet critical temperature control needs. Their resistance to moisture, water ingress, and corrosion further endorses their role in medical ventilators and barbecue ovens, where hygiene and safety are paramount. The robust connections, such as movable copper nuts within 304 stainless steel tubes, allow straightforward integration with minimal maintenance, underscoring why manufacturers prioritize sourcing from a dependable pt sensors suppleir capable of delivering consistently high-quality components.

How manufacturers support customization to fit diverse consumer scenarios

Meeting the nuanced demands of diverse industries requires a pt sensors suppleir to go beyond offering standard components by facilitating tailored solutions that align with unique customer needs. Leading manufacturers understand that temperature sensing situations differ widely—from the measurement points in a refrigerated transport container to sensors embedded in compact medical devices or automotive systems with strict spatial constraints. As a response, they provide customizable options in terms of probe lengths, wiring configurations, and connector types, enabling clients to embed PT sensors seamlessly into complex system architectures. This adaptability extends to production processes where automated pairing and quality control checks preserve sensor uniformity across batches, ensuring that every unit complies with rigorous international standards like CJ 128-2007 and EN 1434. Ongoing technical support, including access to free samples for prototype testing and expert guidance during system integration, empowers consumers to optimize their designs without compromising reliability. The trustworthy collaboration between consumers and a quality-focused pt sensors suppleir elevates the overall performance and longevity of temperature-dependent equipment, allowing the sensors to fulfill their critical role in real-world conditions precisely as intended.

The role of PT sensors supplied by a skilled pt sensors suppleir in modern temperature measurement is unmistakably pivotal, blending accuracy with stability and resilience. These specially designed components, often encased in durable stainless steel and rated for consistent operation across varied industrial and medical environments, mark a noteworthy progression in sensing technology. With the capacity for customization and strict adherence to recognized standards, these sensors not only safeguard processes but also represent a milestone in the journey toward more reliable and precise thermal monitoring. As temperature control remains essential for technological advancement and user safety, such dependable sensors will continue to serve as foundational elements in evolving applications.

References

- Motor PT100 PT1000 Platinum Resistance Temperature Sensor– Overview of PT100 and PT1000 sensors for motor applications

- PT100, PT200, PT1000 Measure Instruments Platinum Resistance Temperature Sensor– Details on PT1000 sensors for measurement instruments

- MCR PT100: The Ultimate NTC Temperature Sensor– Information on MCR PT100 NTC temperature sensors

- PT1000 Thermocouple Temperature Sensor – High-Precision PT100 Probe– Specifications of PT1000 thermocouple temperature sensors

- DS18B20 Waterproof Digital Temperature Probe – Reliable Sensor for HVAC, Aquarium, Freezers & Smart IoT Devices– Features of DS18B20 waterproof digital temperature sensors